Tackling the Challenge of Identifying Reliable Color Removal Solutions for Post-Consumer Recyclates

The innovation team of a leading FMCG firm was tasked with identifying advanced color removal technologies for Post Consumer Recyclates (PCR) to improve the quality of recycled materials. Several critical factors played a key role in this research:

Technology Complexity: With a range of color removal technologies available, each using different mechanisms—such as dissolving contaminants or polymers—the team needed to understand how each technology worked and its potential applications thoroughly.

Feedstock Compatibility: The team had to assess the suitability of each technology for different types of PCR feedstock, ensuring the selected solutions could be effectively applied across a range of materials.

Limitations and Scalability: Known limitations of the technologies, such as efficiency, scalability, and energy consumption, had to be carefully evaluated to avoid investing in solutions that may not perform as required.

Supplier Reliability: Identifying reliable suppliers and developers of the technologies was crucial for successful implementation, and the team had to consider the readiness levels of each technology, both commercially and technically (TRL and CRL).

By identifying the right technologies, the firm aimed to enhance the quality of their recycled materials, making them more suitable for reprocessing and contributing to higher recycling rates and sustainability efforts.

Streamlined Supplier Selection for Optimal Technology Implementation

The team was provided with a detailed list of suppliers, ranked based on key parameters that were most relevant to their needs. These parameters included:

- Applicability to different types of plastics: The ability of the technology to handle various plastic feedstocks.

- Recycling process type: Whether the process involved chemical or mechanical recycling methods.

- Degree of commercialization: The readiness level of the technology, both in terms of technical feasibility and market availability (TRL and CRL).

Based on these factors, the suppliers were categorized into four tiers, with Tier 1 representing the highest priority suppliers that best met their criteria, followed by Tiers 2, 3, and 4. This structured ranking system simplified their decision-making process, enabling them to focus on the most viable technologies, allocate resources efficiently, and maximize their sustainability initiatives.

Key Findings from the Analysis

The in-depth analysis of various color removal technologies revealed multiple key findings, few of them include:

DyeRecycle

DyeRecycle, a spin-off company founded by former Imperial Chemical Engineering PhD students, developed an innovative circular chemical technology to decolorize textile waste and reuse old dyes.

This unique process works by transferring color from textile waste onto new material, effectively decolorizing the input waste. The resulting white fibers are more easily recycled and carry a higher value. The technology uses an ionic liquid solution to strip dyes from textiles. In this process, 10 g to 500 g of dyed textile strips are loaded per kg of ionic liquid solution, heated between 70 °C to 200 °C. The ionic liquid penetrates the textile fibers, causing them to swell and release the dye, which disperses into the solution. The dye-free textile is then removed, and the solution is cooled and reused to dye new materials. Remaining dye is recovered via adsorption using activated carbon or polymeric adsorbents.

Hong Kong Research Institute of Textiles and Apparel (HKRITA)

The Hong Kong Research Institute of Textiles and Apparel (HKRITA) has developed a supercritical CO2-based solid-liquid extraction process for decolorizing PET fibers, a technique also protected by a patent.

This innovative method utilizes supercritical CO2 as a green Non-Aqueous Solvent Medium (NASM) to decolorize PET fibers without harsh chemicals. CO2 in a state above its critical temperature and pressure helps overcome common challenges, such as preventing fiber damage and reducing toxic by-products. At a temperature range of 90-130°C and pressure range of 140-280 bar, the CO2 penetrates deep into the PET fibers, dissolving and extracting the dyes. This technique achieves a high degree of color removal, allowing the decolorized fibers to be re-dyed and reused.

Research Process- How did GreyB Help?

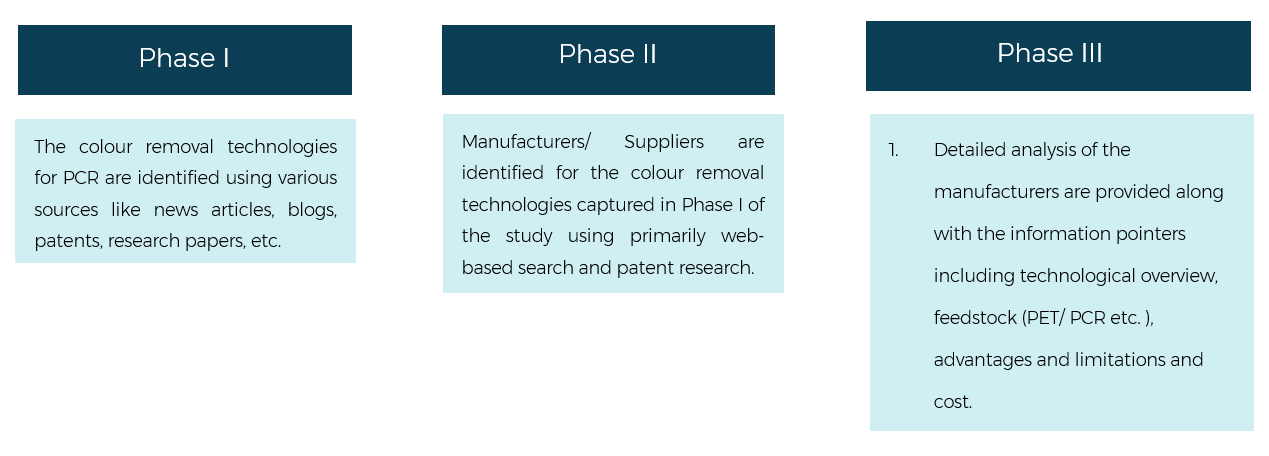

Phase I: Technology Identification

The color removal technologies for Post Consumer Recyclates (PCR) were identified by analyzing a variety of sources, including news articles, blogs, patents, and research papers. This comprehensive literature review aimed to uncover the latest advancements and techniques in the field, ensuring a thorough understanding of available solutions.

Phase II: Supplier and Manufacturer Identification

Once the technologies were identified, relevant manufacturers and suppliers were pinpointed through web-based searches and patent research. This step focused on gathering key information about companies developing or providing these color removal technologies, with an emphasis on their technical and commercial readiness.

Phase III: Detailed Analysis and Recommendations

A detailed analysis of the identified manufacturers was conducted, covering several key parameters. These included a technological overview of each process, the type of feedstock (e.g., PET, PCR) the technology could handle, as well as its advantages, limitations, and cost-effectiveness.

The findings provided the team with a clear, structured framework to evaluate potential solutions, enabling informed decision-making about which technologies and suppliers to prioritize based on their impact and feasibility.

As global plastic consumption rises, the limitations of traditional recycling methods become increasingly evident. Some of them includes:

- Degradation of the material quality of plastics making them unsuitable for certain applications.

- High energy consumption

- High carbon footprint due to chemicals used and emissions produced during processing.

Addressing these challenges is essential for improving the efficiency and effectiveness of recycling systems and achieving greater sustainability in waste management.

If you’re ready to enhance your recycling processes and contribute to a sustainable future, fill out the form below to schedule a consultation with our experts today.