Value Delivered

This approach not only reduced the risks tied to the infringement suit but also simplified the firm’s legal obligations, ultimately turning the case in their favor. By carefully leveraging subtle details indirectly covered in the prior art, a compelling argument was crafted that significantly bolstered the firm’s position.

Problems Solved

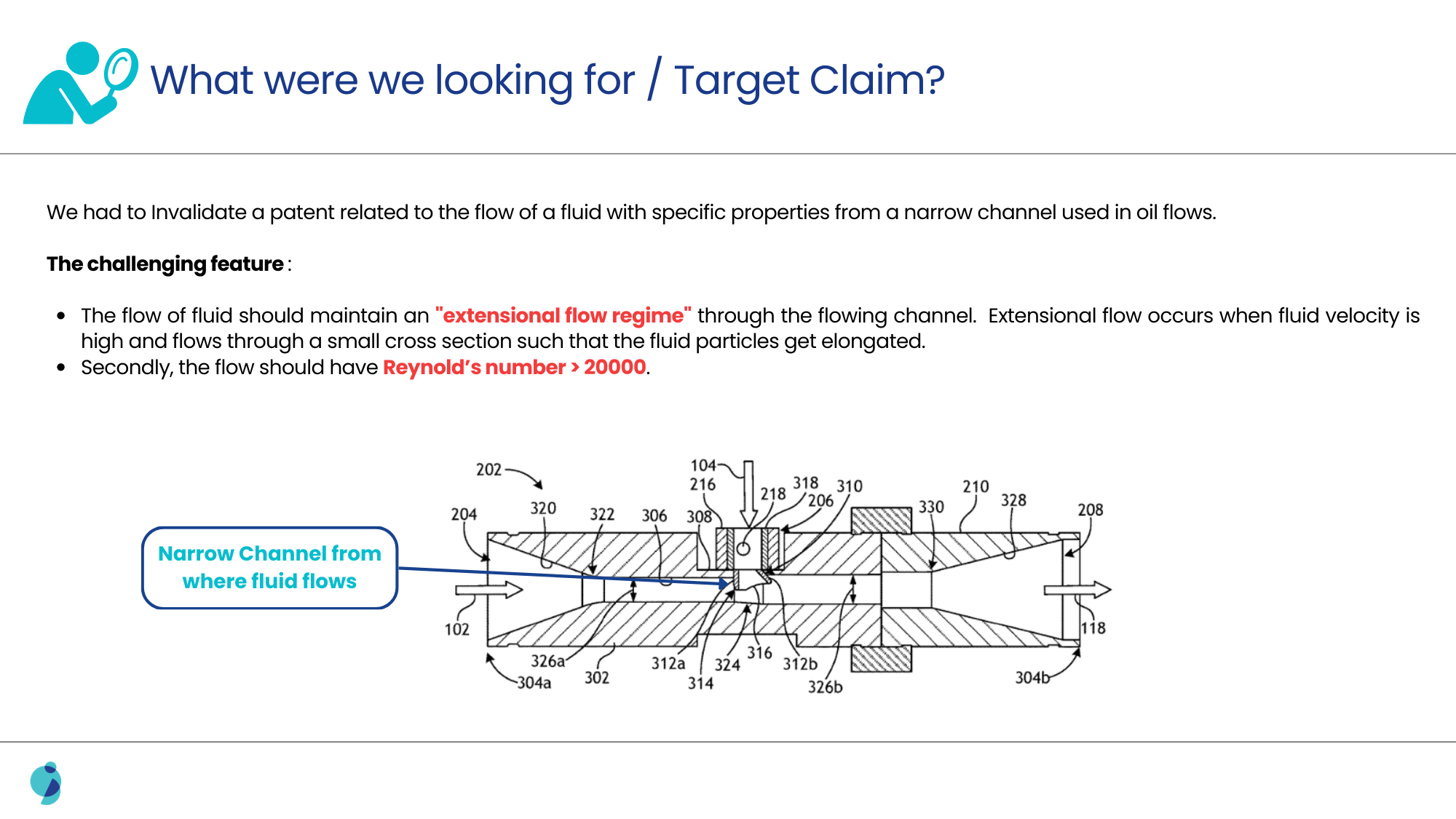

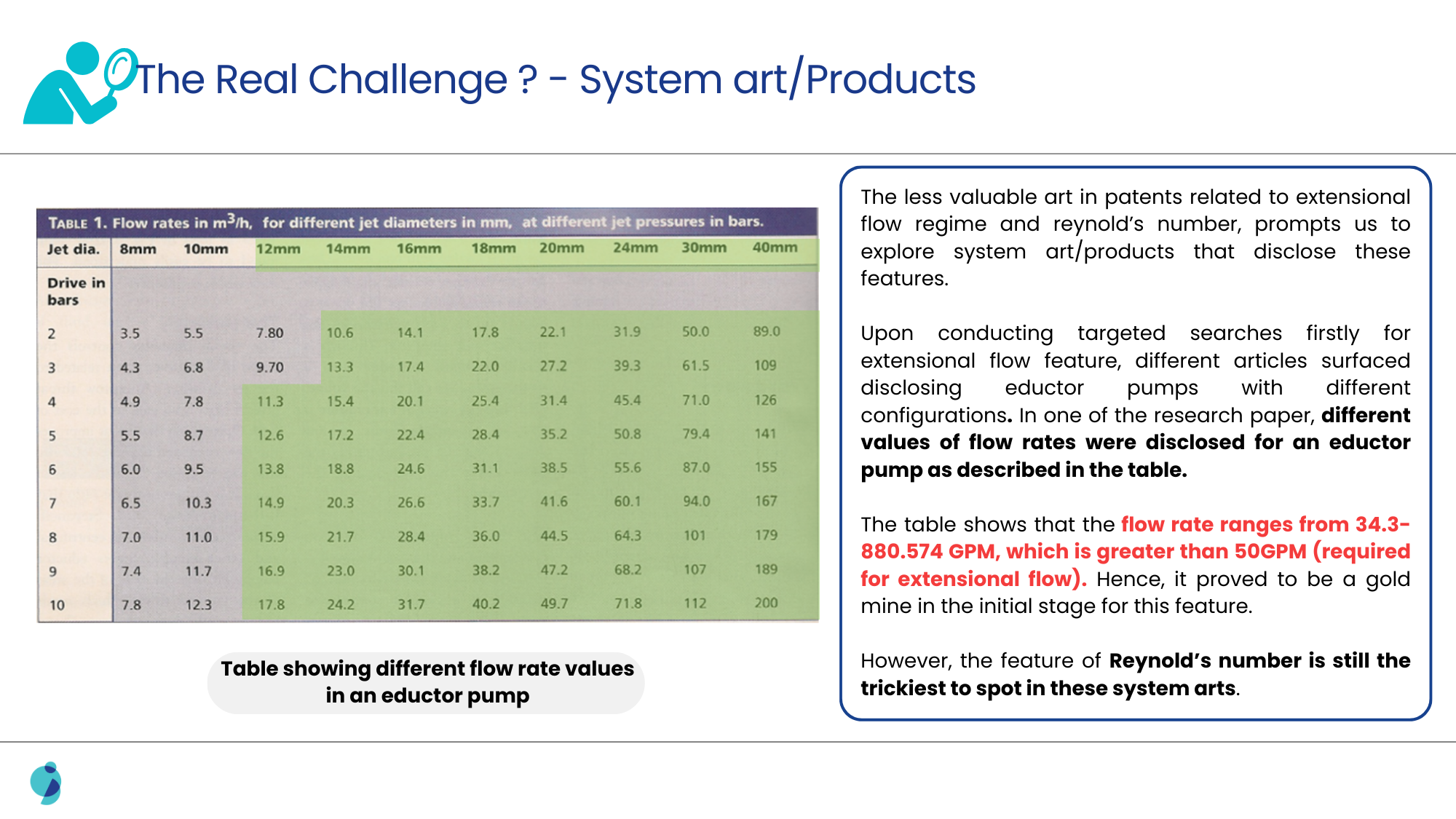

Identifying precise numerical values critical to the case proved challenging due to gaps in existing patents. Many patents lacked explicit references to Reynolds numbers or concentrated on unrelated fluid flow parameters, complicating the development of a precise analytical foundation. The need for extensional flow added further complications, as it led to the inclusion of irrelevant patents from broadly defined application areas, which distracted from a focused analysis.

These challenges hindered accurate data extraction and posed obstacles to drawing reliable conclusions.

Solution Offered

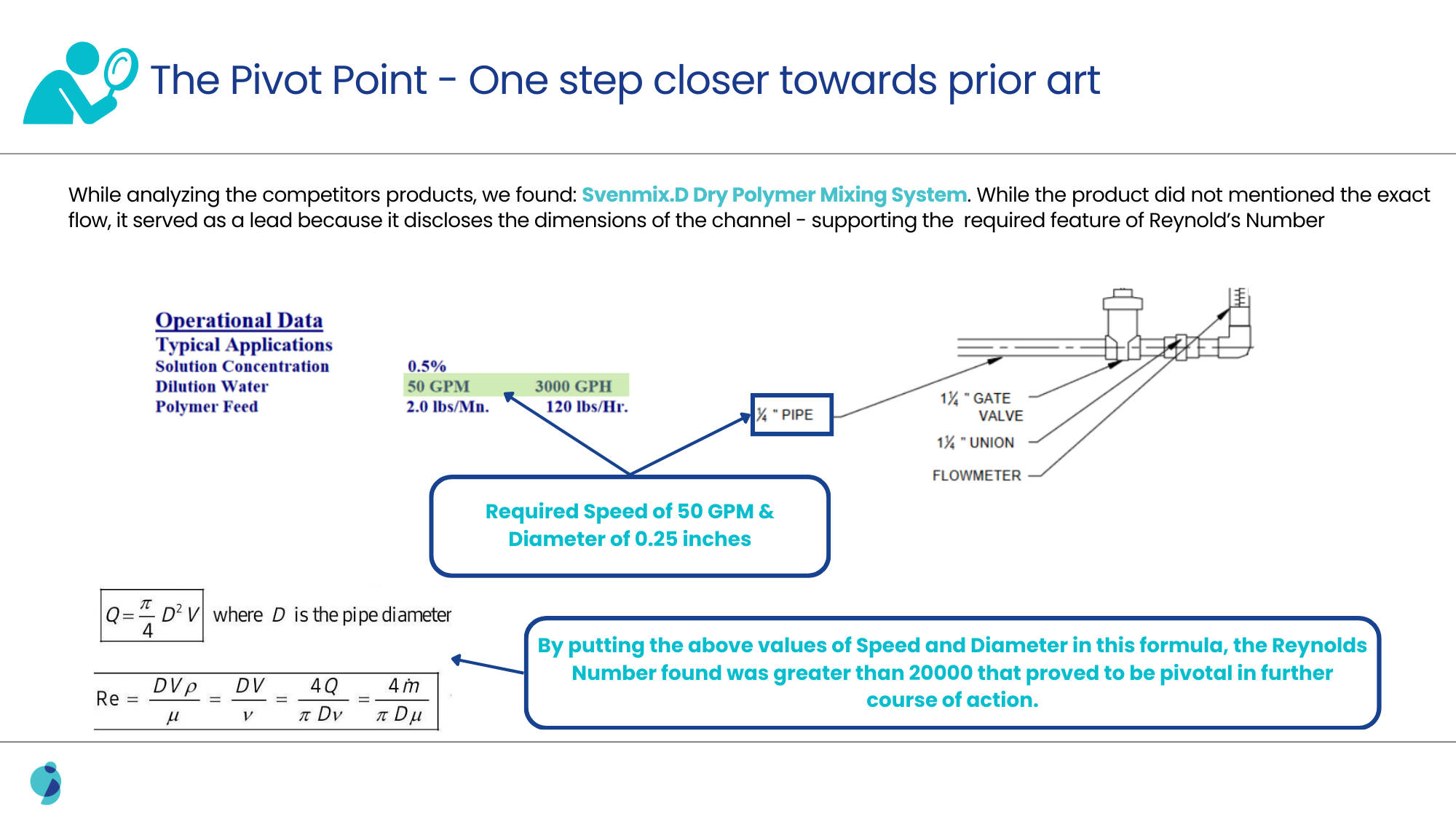

To tackle these challenges, the strategy was refined to focus on factors indirectly linked to the Reynolds number, such as fluid speed and pipe diameter. A thorough analysis of these related parameters in patents and technical documents uncovered secondary indicators pointing to relevant prior art.

Analytical techniques were then applied to calculate the required Reynolds number and its associated features, ultimately revealing valuable prior art that met the case’s criteria.

Get the full case study to discover how, with GreyB’s help, a leading oil & gas firm escaped a major infringement lawsuit.

Request Full Case Study

Download in PDF Format and read anytime. Fill the form to get access to this article.