Overcoming Regulatory and Environmental Challenges by Finding PFAS Alternatives for Sustainable Packaging

The R&D team of a well-known packaging company was tasked with identifying and evaluating alternative materials to replace PFAS-based packaging, as the company sought to align with global sustainability goals. However, several critical factors were influencing their research:

- Environmental Impact: The team needed to find materials that were not only eco-friendly but also met strict environmental regulations.

- Regulatory Compliance: Any alternative material had to adhere to global regulatory standards, ensuring the company could avoid potential legal or compliance issues.

- Manufacturing Suitability: The alternatives had to fit seamlessly into existing manufacturing processes while maintaining product quality and meeting technical specifications.

By addressing these challenges, the company aimed to mitigate the environmental risks associated with PFAS and position itself as a leader in sustainable packaging solutions.

360-degree Analysis of PFAS Alternatives for Compliance, Efficiency, and Quality

The team received comprehensive insights that helped them identify a suitable PFAS alternative, meeting stringent legislative requirements while also enhancing operational efficiency and maintaining product integrity. The analysis highlighted alternatives like Chromatogeny, an eco-friendly chemistry technique that replaces traditional solvent-based coatings, improving the recyclability and biodegradability of paper without compromising its quality. Furthermore, the team benefited from an in-depth evaluation of shortlisted PFAS alternatives, including assessments specific to their application areas, which even involved reviewing supplier materials, such as through a detailed YouTube video.

Key Findings from the Analysis

The analysis offered a detailed understanding of the diverse alternatives of PFA solutions, revealing a range of crucial solutions:

Silica

The dense, glass-like silica material provides excellent barriers against oxygen and moisture in packaging, effectively replacing PFAS. It offers strong resistance to gases and water, maintaining chemical inertness except in solutions with a pH greater than 5. With thermal stability up to 800°C, it withstands sterilization methods such as gamma irradiation. Additionally, it enhances adhesion to natural rubber and is challenging to penetrate due to its glass-like nature. Widely used as a packaging barrier and as an anode for Li-ion batteries, it offers versatile applications.

Chromatogeny

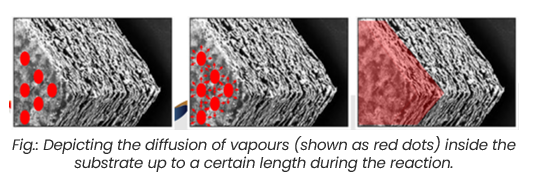

Chromatogeny is an eco-friendly chemistry technique devoid of solvents, designed with the primary goal of providing hydrophobic properties to diverse substrates, such as paper, starch, PVOH, minerals, boards, and more.

Innovatively replacing solvent-based coatings, this grafting method imparts hydrophobic properties to paper without compromising its integrity. This advancement significantly boosts paper recyclability and biodegradability compared to conventional coatings.

As of 2019, Centre Technique Du Papier achieved pilot-scale industrial feasibility. By 2023, Cellulotech is advancing with an industrial pilot, targeting commercialization within the next two years.

Research Process-How did GreyB Help?

Material Identification and Evaluation

To identify suitable PFAS alternatives, we conducted a thorough review of various sources, including patents, research papers, products, blogs, and supplier videos. This extensive research enabled us to gather a comprehensive list of materials that could replace existing PFAS in packaging.

Evaluation and Analysis

The identified materials were then evaluated based on key criteria:

- Technical properties: Barrier strength, biological inertness, and other relevant performance metrics.

- Business considerations: Cost-effectiveness and the technology readiness level of each alternative.

- Certifications and sustainability: Compliance with food contact certifications, both in the US and EU, and aspects like biodegradability and recyclability.

Structured Framework and Recommendations

The analysis provided the team with a detailed, organized assessment of the most suitable PFAS alternatives. Materials were categorized into three tiers:

- Tier 1: Ready for immediate adoption based on their strong fit for needs.

- Tier 2: Promising options that require further development or monitoring.

- Tier 3: Alternatives with limited potential for the team’s specific requirements.

This structured evaluation helped the team make informed decisions about which PFAS alternatives to prioritize, ensuring regulatory compliance, sustainability, and operational efficiency.

Choosing sustainable alternatives to PFAS materials comes with its own set of challenges, from assessing environmental impact to ensuring regulatory compliance and finding the right eco-friendly solutions. Navigating these complexities can slow down your progress and add unnecessary costs.

Identifying the best PFAS alternatives is crucial to meeting sustainability goals without compromising on quality or efficiency. Whether it’s selecting the right materials, ensuring compliance, or forming strategic partnerships, GreyB can help.

If you’re ready to find the best sustainable solutions for your packaging needs and move forward with confidence, fill out the form below to schedule a consultation with our experts today.