The strategic shift towards smart packaging is poised to revolutionize how dairy products are packaged, distributed, and consumed, fostering a more sustainable and consumer-centric approach in the industry.

By integrating smart packaging solutions, dairy companies like FrieslandCampina aim to enhance operational efficiency and provide an enriched consumer experience through personalized offerings.

Other industry giants like Lactalis and Nestle are also innovating in this domain. What groundbreaking solutions have they developed thus far?

Let’s take a look.

Recent Developments in Sustainable Dairy Packaging

By 2025, FrieslandCampina aims to achieve 100% recyclable packaging materials, and by 2050, they aspire to adopt circular packaging that can be reused, recycled, or composted. To realize these goals, the giant has embraced eco-friendly packaging made from 86% renewable plant-based materials.

Additionally, they have joined forces with companies like D&G Pacific Corporation to establish a multi-layered plastic upcycling facility, further demonstrating their commitment to sustainable packaging practices.

Lactalis Group, another prominent player in the industry, has adopted a “right pack” strategy to reduce packaging material usage. By implementing this strategy, they have successfully reduced plastic usage by 9.5% on their milk bottles, resulting in a reduction of 800 tons of plastic per year.

In 2021, Lactalis Group partnered with INEOS to introduce HDPE Milk Bottles made from circular polyethylene derived from post-consumer recycled material, showcasing their dedication to incorporating recycled materials into their packaging solutions.

Nestle has also taken significant steps towards sustainable packaging of its dairy products, similar to how it made recyclable KitKat packaging.

Curious to find out about their recent innovations in dairy packaging?

Find more details in our latest Dairy Trend Report.

Fill out the form below and find the report in your inbox!

Further, to tackle the challenge of recycling colored caps into food-grade packaging, Muller, a prominent dairy company, has transitioned from colored to clear caps for their milk bottles.

By converting their entire range to clear caps by summer 2023, Muller aims to facilitate the reuse of the material within the food sector, contributing to a more sustainable packaging approach.

Recent Developments in Smart Dairy Packaging

Dairy companies increasingly utilize QR code technology to provide consumers with additional information. Nestle, for example, incorporates QR codes on their packaging to offer customers details about the nutritional profile and environmental/social impacts of their products.

FrieslandCampina has also introduced QR codes for their infant nutrition brand, Friso, in partnership with Kezzler, a tech company based in Norway. This QR code tracking platform enables consumers to trace the journey of their product from farms to their hands.

In 2020, Danone implemented laser-printed QR codes on their baby formula products to ensure product authenticity and traceability. Each item has a unique, dual-serialized QR code. This technology has since been extended to their plant-based products as well.

Additionally, Danone collaborated with Impacx (formerly Water.io), an Israeli smart packaging startup, to utilize its smart cap technology. This cap connects to an app that monitors the user’s water consumption, guiding proper hydration.

Apart from traceability, dairy companies are leveraging smart packaging for customer engagement. For instance, DCI Cheese Company and The Laughing Cow utilize smart packaging solutions for promotional campaigns. Brave Robot Ice Cream, under The Urgent Company, uses smart packaging to showcase its carbon footprint to customers, highlighting its commitment to sustainability.

Conclusion

The Governments and regulatory bodies have pushed sustainable packaging over the past few years, prompting the adoption of environmentally-friendly packaging solutions by dairy companies as well.

Meanwhile, the story behind the rise of smart packaging is slightly different — it is gaining popularity not due to regulatory requirements but the advantages it offers.

That’s why this trend will grow as technology advances over the years.

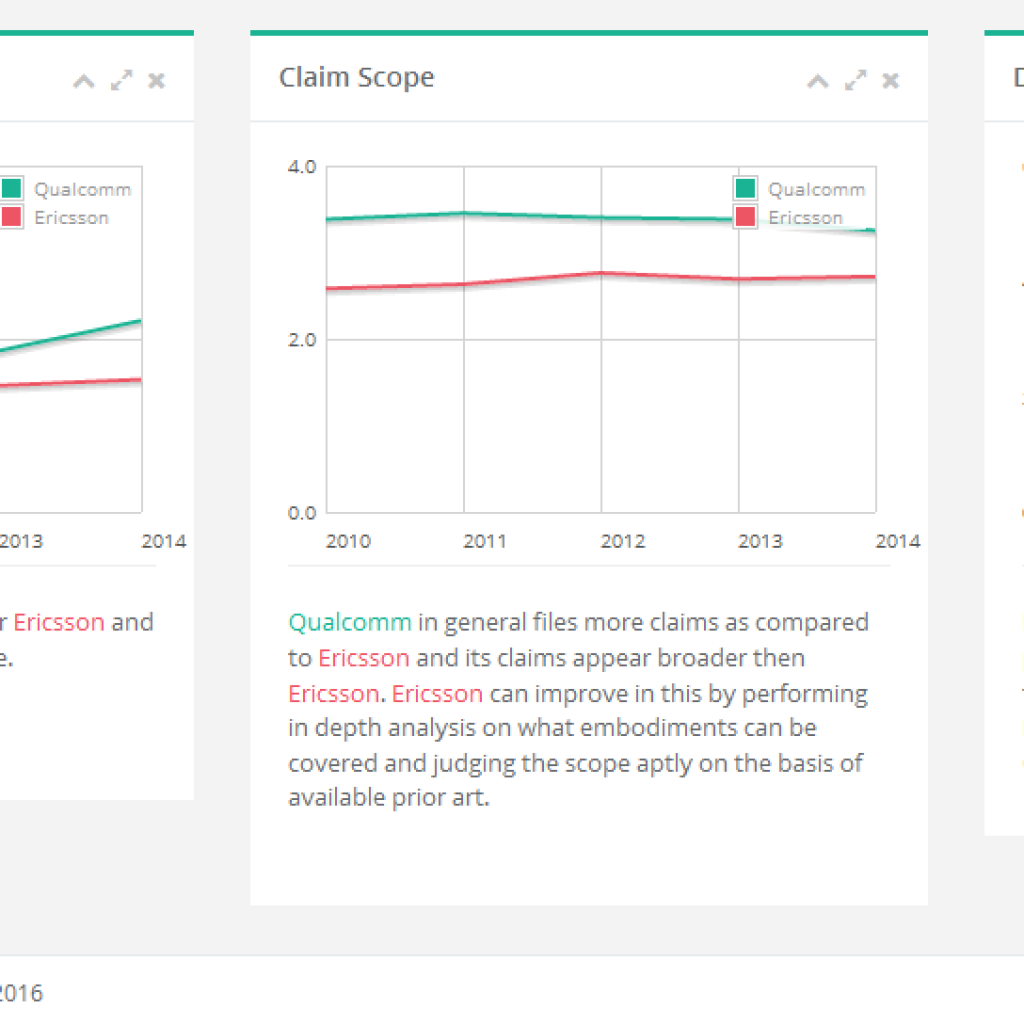

Authored by – Harleen, Vanshika, and Nidhi, Patent Analytics

Edited by – Ridhima, Marketing

Also Read: A Closer Look at 8 Transformational Dairy Industry Innovation Trends in 2024