Apple has suppliers in more than 30 countries around the world.

GM, to produce the Chevy Volts, uses more than 800 suppliers.

Businesses face many challenges – from natural calamities to man-made disasters, and from govt. regulations to customers’ tendency to blow hot and cold. The complex supply chains are only adding to the woes by exacerbating the risk.

Among all these issues, the issue of patent litigation in the upstream and downstream supply chain is one of the major concerns for corporations. A global supply chain for sure has an impact on the success of a product; however, it also makes a company susceptible to land into patent litigation.

A situation where you get sued for using a component manufactured by your supplier in the upstream supply chain could lead you to pay heavy damages or royalties adding an unforeseen financial burden. Hence, it is vital to know who you are doing business with.

Adding the indemnifying clause in the vendor agreement is a no brainer here. An indemnity clause states that a vendor won’t use protected inventions in the material supplied, and in case it does, and you get sued for patent infringement, it will indemnify you by litigating the case. Till now everything that we are saying is pretty basic and 99% chances that you are already taking care of it.

That said, to what extent your vendor indemnifies you depends on the vendor’s financial resources. If a plaintiff has deeper pockets than your vendor or you combined, the indemnifying clause may become meaningless. In such a case, even if your vendor isn’t infringing, scarce financial resources could turn the table for you and you may not like it.

A good strategy, thus, is to quantify the risk before letting someone enter into your upstream or downstream supply chain, and create a mitigation strategy before selecting a vendor. Today, during our brief time together, I’ll share a few strategies that could help identify the risk which can then help you find ways to mitigate it. Let’s start.

Supply Chain Management: Patent Risk Mitigation Strategy

A normal patent risk mitigation strategy helps you tackle litigation in the courtroom. However, a smart patent risk management strategy can help eliminate the threat beforehand in a way that you find no need to go to a courtroom. It deters PAEs and other patent asserters, and can also help you strike a patent licensing deal at a lower cost.

Alignment of business strategy and risk appetite should minimize the firm’s exposure to large and unexpected losses. In addition, the firm’s risk management capabilities need to be commensurate with the risks it expects to take.

― Jerome Powell

Your supply chain patent risk mitigation strategy, hence, should include the following elements of your business ecosystem:

- Your suppliers

- Competitors of your suppliers

- Suppliers of your suppliers

- Competitors of your suppliers’ supplier

- Your partners

- Your customers

- NPEs that could sue your suppliers

- NPEs that could sue your customers

- Big corporate patent asserters that could sue your suppliers

- Big corporate patent asserters that could sue your customers

It is vital to building a patent litigation threat model by identifying all such sources from your supply chain – upstream as well as downstream – that could create a nuisance. Giving your supply chain a holistic view can ensure that an undefined threat doesn’t escape under the radar. It can help you identify the unknown which you can then turn into first a patent strategy, and finally can align it with your business strategy.

There are known knowns. These are things we know that we know. There are known unknowns. That is to say, there are things that we know we don’t know. But there are also unknown unknowns. There are things we don’t know we don’t know.

― Donald Rumsfeld

Using Taxonomy to build a Risk Mitigation Strategy for Supply Chain

What is a taxonomy?

Let’s consider an example where you ask me to find everything that constitutes a vehicle. How should I go about it? Perhaps, a better strategy is to ask questions like:

- What are the different kinds of vehicles?

- What are the different parts of a vehicle?

- What kind of material is used in different parts?

- What are the applications of different kind of vehicles?

- What kind of features are available in vehicles?

After finding answers to these questions, I can categorize them; for example:

- Material – Steel, Tin, Rubber, Plastic, Iron

- Parts – Tyre, Chassis, Engine, Steering wheel, Brakes, Suspension

- Entertainment features – Speakers, Screens, Music Player

- Type – Cars, Trucks, Tractors, Buses

- Application/Uses – Logistics, Agriculture, Transportation

Now, if someone has to explain what all constitutes a vehicle, such a complete breakdown will help anyone understand it better. Similarly, if one can create such a breakdown for a technology, s/he can better understand that technology domain.

Taxonomy, thus, is a breakdown of any technology to its minutest (or broad in some cases) detail that can give a complete picture about what all is actually present in that domain, what constitutes it, and what all is related to it.

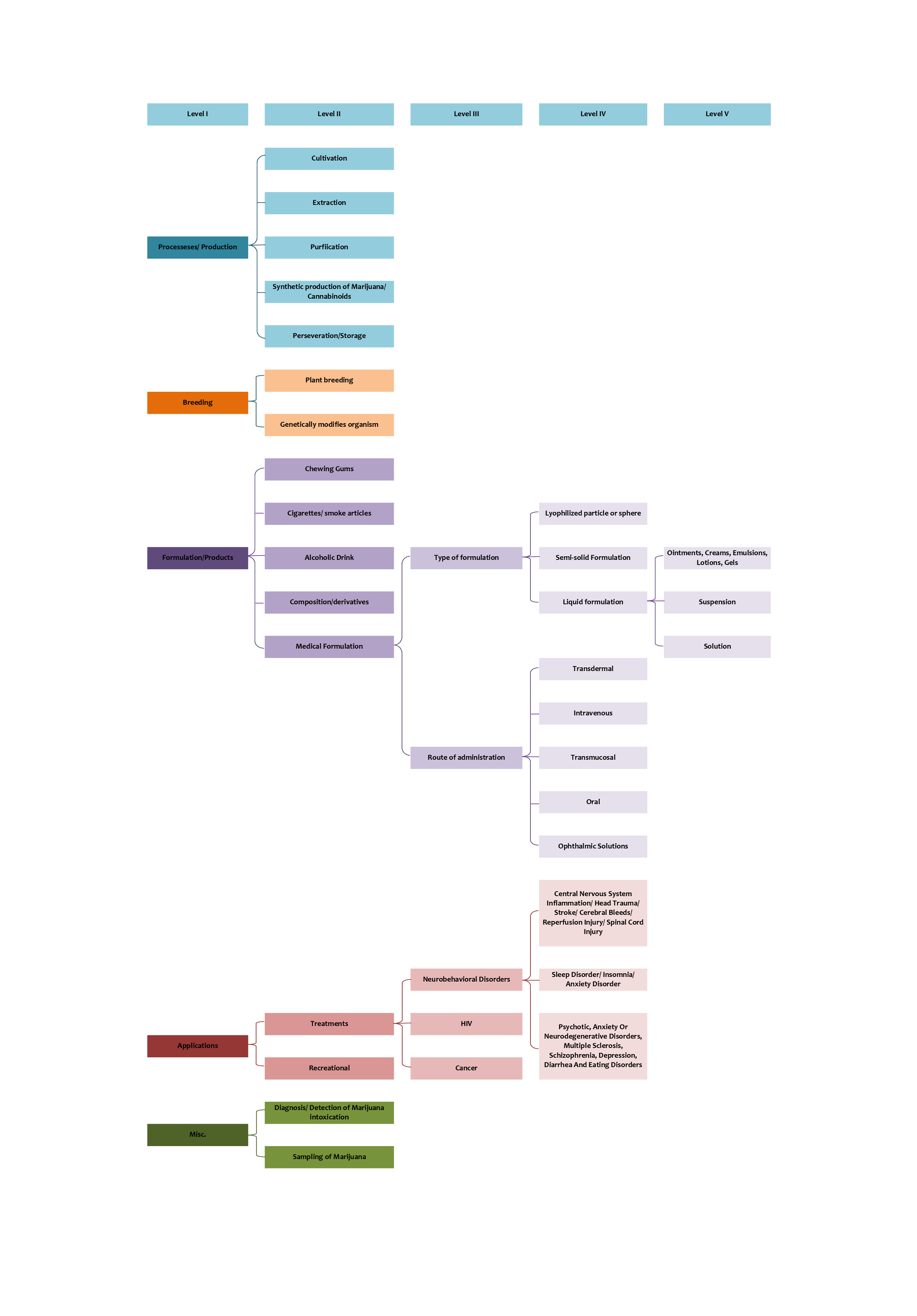

Below is an example of a taxonomy for the Marijuana domain:

Similarly, a taxonomy based on your supply chain could be created where all the suppliers’ technologies you are using could be listed and broken down to the minutest component. Let’s take an example to drive the point home.

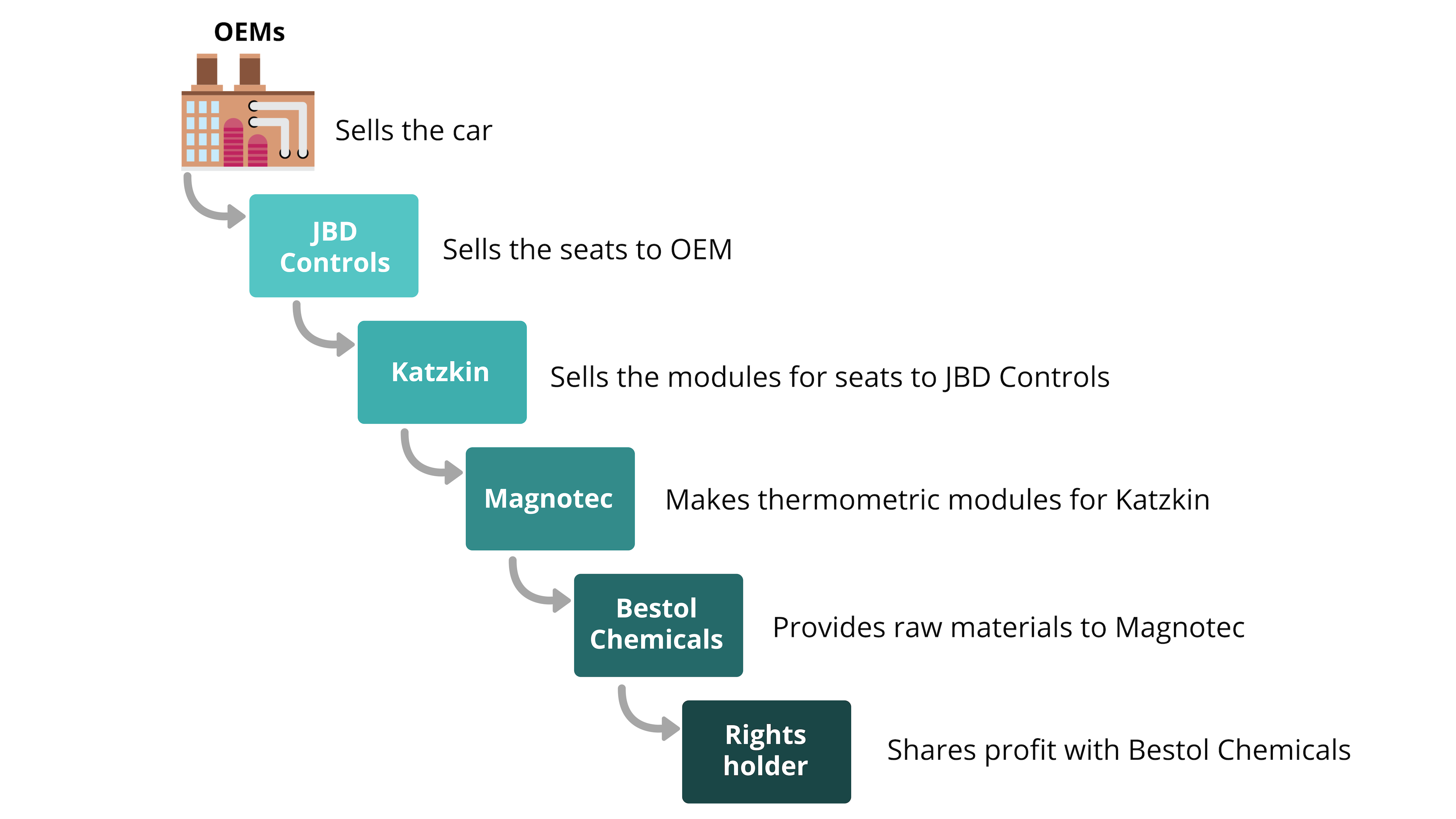

Let’s assume that you’re an automobile manufacturer (OEM). OEMs in the automobile industry have complex supply chains. A component/product may reach an OEM’s manufacturing facility through a network with three to five levels of suppliers. For example, for a climate-controlled seat, there are 5 levels of suppliers (as depicted below).

The automotive industry is known as “the industry of industries”. It uses outputs from almost all types of manufacturing industries (mining, steel, plastic, rubber, semiconductors, chemical, batteries, glass, etc.) in the upstream phase and also in the downstream (finance, marketing, logistics, software, fashion, insurance, etc.)

Moreover, in the last few years, electronic vehicles and driverless technology have gained traction. This has added more complexity to the supply chain.

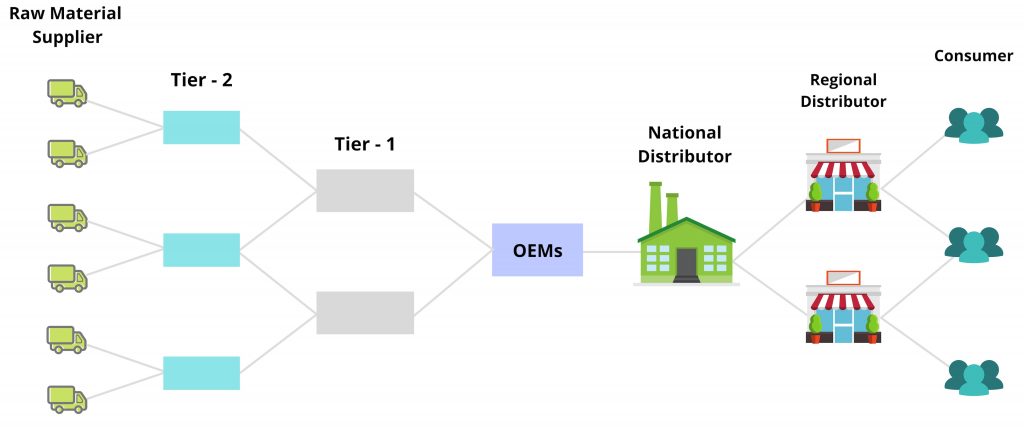

A broad supply chain (just for exemplary purposes) for a vehicle OEM is presented below.

Similarly, a taxonomy based on your supply chain could be created where all suppliers’ technologies you are using could be listed and broken down to minute components.

In the taxonomy, corresponding to each tiered supplier – upstream as well as downstream – patents could be categorized filed by the supplier or anyone else. Apart from that, patents in the OEM’s portfolio can be categorized as well.

You can use such a taxonomy to find answers to questions like:

- How to identify gaps in the patent filing that can be exploited for strategic negotiation?

- How you can use it to find patents you already know that you can use for countersuing?

- How it can be used for filing/acquiring patents that could help keep litigation threat at bay?

Such categorization will give you a holistic view of threats and opportunities. Once done, you can then plot a SOTO matrix to decide further action.

Wondering what is SOTO and how it will help you mitigate risk? Let’s find out.

How to use a Taxonomy and SOTO Matrix to Mitigate Threat and to have an upper hand in negotiation?

Once you have a taxonomy plotted for your patent portfolio, and the technologies of the vendors used in your supply chain – upstream as well as downstream – you can quickly identify the areas where:

- Your supplier/vendor hasn’t filed enough patents, but competitors, NPEs and Corporate Patent asserters have (Threat)

- Your supplier/vendor has considerable filing, but not by NPEs, competitors, and corporate patent asserters (Strength)

- Neither your supplier nor its competition and other corporate asserters has filed enough patents. This could be an upcoming potential tech area to explore for them and maybe one of their products/services is using/use it ( Opportunity)

- You have filed patents that a product/service of your supplier or its competitor is using. (Overlap)

Let’s kill the confusion before it is born: SOTO is not SWOT.

On the first look, one can confuse the SOTO matrix with a SWOT matrix or a Johari Window. It is inevitable as those are the theories we took inspiration from to come up with this. However, it is neither a SWOT matrix nor a Johari window.

In a SWOT matrix, for example, you can put the Harmful and Helpful metrics in a row or a column. In SOTO, that isn’t possible as more than three cells – in our example, there are three – out of four cells are in your favor.

Let us now have a look at how you could use the SOTO matrix to mitigate litigation threat and gain an upper hand in negotiation.

Let us now have a look at how you could use the SOTO matrix to mitigate litigation threat and gain an upper hand in negotiation.

How to use SOTO Matrix to mitigate litigation threat?

To have a competitive advantage, as a next step, you have to identify a strategic fit among Strength and Threat – S-T strategies, and Strength and Overlap – S-Ov strategies. Let’s have a look at how these could help you.

S-T Strategy for Counter-Suing

Ideally, these tactics should be used by the vendor you are working with. In the patent litigation world, it is common to see a defendant counter-suing a plaintiff for infringing its patents. This strategy can work well with competitors leading to cross-licensing of patents between a plaintiff and your vendor.

It is always better to be prepared than to be sorry later. Thus, in case your vendor misses finding patent(s) that could be used for countersuing and cross-licensing later, you can do that from your end.

Let’s retake the example of the automobile OEM. After having generated the taxonomy, you would already have the entire patents in your supply chain categorized, which you can then use to easily find patents for countersuing.

In fact, this combination provides you an early warning and countermeasure sensor. Once you categorize all the patents on technologies used in your supply chain, you can easily see where your suppliers may trip. As a countermeasure, you may acquire/file patents that could be used for countersuing or deterring.

Also, if you find beforehand where your suppliers may trip, you can use this opportunity to negotiate a deal in your favor.

Simply put, Strength-Threat (S-T) strategy is you playing by your and your vendor’s strength to mitigate risk. However, it is worth noting that this strategy won’t work when an NPE sues your vendor.

Op-Ov Strategy for Upper hand in Negotiations

The tech areas falling in the Opportunity quadrant of the SOTO matrix can help you get leverage in the negotiation with your vendors and to mitigate risk as well. In general, your vendor has a threat of getting sued for not filing/getting a license to patents their product/service is using.

As you have already got all the patents on technology used in your supply chain, you can easily see patents filed by your organization used by your suppliers (if any). Else, you can look for universities and individual inventors, whose patents might be being overlapped by your vendors. You can then consider approaching them for purchasing or getting a license for the patents.

Also, depending on the level of threat, you can find universities to collaborate from the same taxonomy. This partnership could be used for filling whitespaces you detected by filing patents in those areas.

Further, if you have such patents which could be infringed by one of the products/services by your vendor or a plaintiff that sued your vendor or you, these patents could be used for countersuing, cross-licensing, or simply to have an upper hand during negotiation with your vendor.

The patents falling in the Overlap quadrant similarly could be used for countersuing or to have an upper hand in the negotiation.

S-Ov Strategy as bargaining chips to mitigate litigation

The Strength-Overlap quadrant could help you combine the strength of your patent portfolio and that of your vendor to build a risk mitigation strategy before/after you or the vendor get sued for patent infringement.

This strategy can be pretty effective when your/your vendor’s defendant is working in a technology area where you have strong IP, whereas the defendant doesn’t. Your patents could be used as bargaining chips for cross-licensing and avoiding litigation.

If you have IP in areas that have a significantly higher ROI – which the defendant is in dire need of – you could even gain an upper hand in negotiation and amass licensing royalties at the same time, while avoiding the threat of litigation.

Action Points

- To avoid unpleasant surprises, the threat of patent litigation in the upstream and downstream supply chain is important to quantify. Giving a holistic view of the patent landscape in your entire supply chain can help you build an Early Warning and Control System (EWCS)

- A taxonomy based on the technologies used in your entire supply chain is one approach to build such an EWCS. The next step is to use this taxonomy to plot a SOTO matrix. The different quadrants of the matrix could help in the following way:

- S-T Strategy for Counter-Suing

Under this tactic, you use the strength of your vendor’s patent portfolio to mitigate litigation threats. You can find patents in your vendor’s portfolio that could be used for countersuing a plaintiff. This is a common move followed in patent litigation.

-

- Op-Ov Strategy for Upper hand in Negotiations

The Opportunity quadrant of the SOTO matrix helps you know the tech areas where your vendor, or a plaintiff that sued your vendor, are infringing patents – of yours or of others. If your portfolio has some of those patents, you can use it for having an upper hand in negotiations.

-

- S-Ov Strength

Here you combine your and your vendors’ patent portfolios to build a threat avoidance shield.

Authored By: Nitin Balodi, Team Lead, Marketing.