Due to its versatility and variety of tastes, the global demand for cheese is astoundingly high. However, manufacturing cheeses the traditional way remains far from being sustainable.

NRDC listed cheese among the top foods contributing to the increase in emissions between 2005 and 2014. In addition to ecological concerns, cheese production puts tremendous strain on animal welfare. The cattle that usually live for 20 years succumb within 4 to 6 years when used as livestock.

Although the ill effects of cheese production have been historically evident, sustainable alternatives have been nonexistent – until now!

Enter- precision fermentation. It’s the process of producing natural dairy proteins using microorganisms without animals. This process is significantly more eco-friendly and resolves the taste and texture issues often associated with plant-based cheese alternatives. Interestingly, even government entities are working with companies to make precision fermentation mainstream.

This report will discuss the benefits of using this process, the precision fermentation companies innovating in this field, and the challenges to foresee.

Why Choose Precision Fermentation for Cheese Production?

The global precision fermentation ingredients market is estimated to be worth $2.8 billion in 2023 and will reportedly reach a staggering $36.3 billion by 2030. When the price of cheese generated using milk from microorganisms becomes equivalent to conventional dairy, animal-free cheese will claim a 33 percent market share.

The Asia Pacific region is projected to see the highest growth in the precision fermentation market during the forecast period due to the increasing demand for alternative proteins, rising disposable income, and growing awareness of environmental and animal welfare issues.

Furthermore, 79% of the precision fermentation market share would come from traditional cheese consumers. This undeniable potential of sustainable cheese production has garnered interest from investors. Global investment in precision fermentation companies increased to almost $600 million in 2020.

Recommended reading: Plant-based innovations that make dairy-free products consumer-acceptable

Revolutionary Precision Fermentation Companies to Explore

1. Change Foods

Founded in 2019, Change Foods creates sustainable cheese using precision fermentation techniques. The company has raised $15.3 million in funding, $12 million of which came from a recent seed extension round and another $1 million from an Australian Commonwealth Government grant. They’re engaged in strategic collaborations in preparation for launching their first products globally.

Change Foods Partnerships and Collaborations

1. Ministry of Economy, UAE

Change Foods, in collaboration with the UAE Ministry of Economy, designed to establish a specialized commercial manufacturing plant in Abu Dhabi to produce animal-free milk protein casein. This initiative, supported under the NextGen FDI program, shows the company’s plans for expansion and positions it as a global export hub for animal-free dairy.

2. Upfield

Upfield owns many of the global leading brands in the category, including Country Crock and I Can’t Believe It’s Not Butter. In 2020, Upfield added plant-based cheese to its portfolio when it purchased Violife’s parent company, Arivia.

Collaborating with an experienced company like Upfield can help Change Foods navigate the alternative category and help make its cheeses stand out.

3. Sigma Alimentos

Sigma is a Mexican multinational food processing company well-versed in the cheese market. It has cheese and yogurt brands in 18 countries.

This partnership can give Change Foods deep category knowledge and wide-reaching distribution. Sigma has also been active in the food tech space. Last year, the company made a minority investment in The Live Green Company, which uses an algorithm to reformulate processed favorite foods with plant-based, clean-label ingredients. The investment helped Live Green expand its products to several international markets.

Change Foods’ Innovations

Change Foods has filed a patent application for the process and composition of their dairy-like foods, which discuss the cheese’s constituents, chemical balances, etc.

Recommended reading: Plants or Fermentation-based Dairy: What should you focus on?

2. Formo

Formo, a Berlin-based precision fermentation innovator, raised a record-breaking $50 million in funding through Series A financing by EQT Ventures, Elevat3 Captial, and Lowercarbon Capital.

The company describes its process as using microorganisms to write copies of cow genes that produce milk proteins. Formo makes several kinds of cheese: Le Kreuzberg, Athena, Charlottenbourg, Cité Bleu, and Frischhain. Each has a unique flavor and texture. Formo claims all their sustainable cheeses are lactose-free and indistinguishable from the real ones.

Formo’s Partnerships with Brain Biotech

Formo partnered with BRAIN Biotech to accelerate its scale and cost competitiveness. The partnership will enable Formo to produce its bioidentical milk proteins at scale, which would be a significant step towards the industrial-scale production of animal-free cheese.

Powered by substantial funding and increased R&D capacity, Formo plans to expand its product portfolio to host various European dairy specialties such as mozzarella and ricotta.

3. Wageningen University of Research

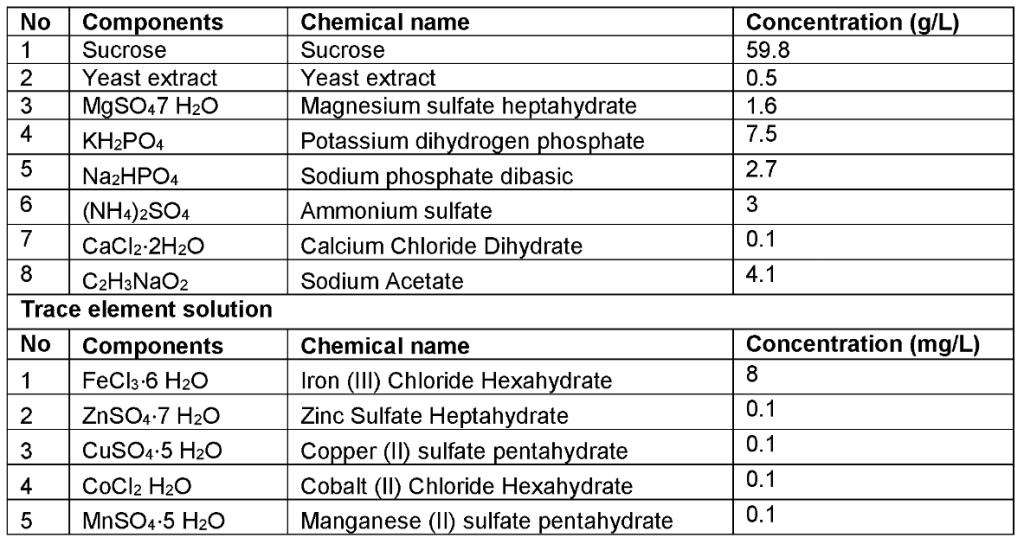

Scientists at the Wageningen University of Research are experimenting with developing cheese through protein transition and precision fermentation. These researchers have identified that eighty percent of the proteins in cow’s milk are caseins, which are essential for cheese making. They’re achieving fermentation using yeasts combined with a piece of DNA that contains the instructions needed to produce casein.

They describe a solution for farmers to use this method by owning a fermentation tank alongside growing sugar-producing crops to sustain the microbes. In addition to these advancements, they are also investigating the use of recombinant proteins as a more sustainable alternative to animal-derived protein, focusing on the milk protein β-lactoglobulin.

Wageningen University’s Partnership with Those Vegan Cowboys

Those Vegan Cowboys is a company established by the founders of the Vegetarische Slager. They are developing new vegan foods indistinguishable from milk, cheese, yogurt, and butter in flavor, structure, nutritional properties, and value. This project aims to develop an animal-free alternative to cow milk protein.

Discover more such comprehensive insights on the dairy industry trends for 2024. Fill out the form below to receive the full report directly to your inbox!

Advantages of Precision Fermentation over Traditional Methods

Sustainability

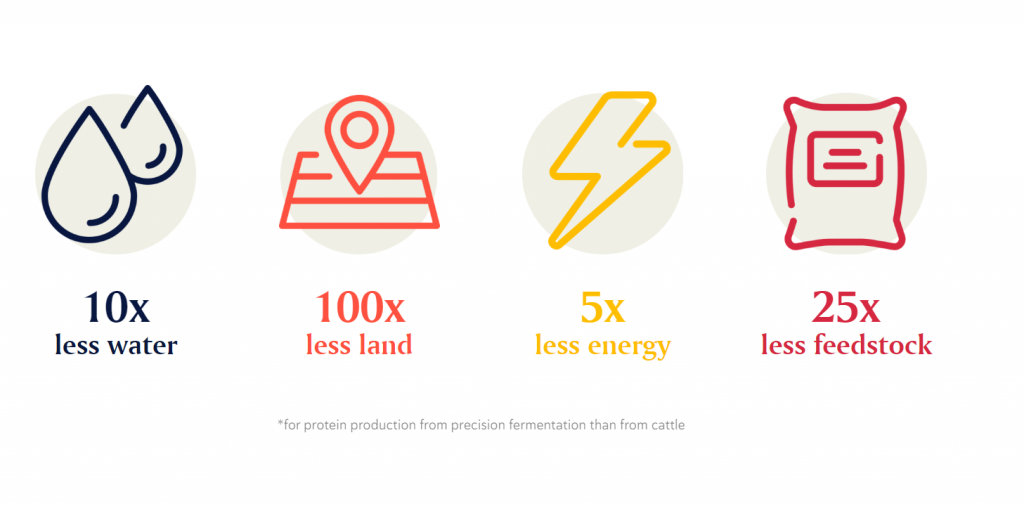

Precision fermentation cuts water and greenhouse gas emissions involved in cheese production. For instance, producing a kilogram of cheese traditionally emits 23.88 kg of CO2. Precision fermentation can produce indistinguishable dairy products with a fraction of the carbon emissions, land and freshwater use.

Purity and Hygiene

Since precision fermentation does not require livestock, the cheese produced through it is free from antibiotics, hormones (estrogen, cholesterol, etc.), pus, and other harmful byproducts of intensive animal farming.

Taste and Texture

Precision fermentation has the upper hand in taste and texture, which plant-based cheese alternatives often struggle to achieve.

Innovation and Versatility

The high functionality of the milk proteins produced through precision fermentation can create a wide range of cheeses, from fresh types like ricotta to aged and ripened cheeses such as Gruyère.

Challenges that Precision Fermentation Companies Face

Scaling Up

Most precision fermentation startups are still in the nascent stage. The availability of fermentation infrastructure operating at scale is severely limited. Investments will take time to meet the needs of large-scale fermentation and downstream processing facilities.

Cost

The cost of production is a significant challenge. Precision fermentation has seemingly resolved the challenge of approaching the stretch-and-melt characteristics lacking in cheese alternatives, but reaching scale and price compatibility are the next frontiers.

Large-scale Acceptance

Steel tanks lack the familiarity of cows. A quarter of respondents to a survey in America aren’t keen to try “precision-fermented” fare. Perhaps that’s why producers prefer to call it “animal-free” instead.

Regulatory Hurdles

Regulatory challenges can also pose a significant obstacle. Different countries have corresponding regulations regarding producing and labeling food products, which can affect the marketability of precision-fermented cheese products.

Conclusion

Despite several years of research, precision fermentation companies that make animal-free cheese products still have a long road ahead. However, microbe-based dairy products like sustainable cheeses are just one among the many dairy industry trends for 2024.

Learn more about the eight new transformational trends shaping the Dairy Industry’s future.

Authored By: Hemanth Shenoy, Market Research