Consumers have become more cautious since COVID knocked on our doors. Using hand sanitizers has become an ideal, surface disinfectant, a commodity. We also saw a similar trend in the textile industry – antimicrobial medical textiles.

A survey conducted by Ascend Performance Materials found that 82% of people are likely to buy apparel with no-odor technology. This is because the textile stays fresher for longer by inhibiting mildew, fungi, and other microbes. In fact, 89% of no-odor buyers are even willing to pay a premium.

Healthcare is the most researched of the varied applications of antimicrobial textiles. Especially in face masks.

Around 70% of the patents on antimicrobial textiles talked about face masks as an application.

One of the reasons is the excessive use of single-use masks during COVID, which has raised sustainability concerns. As a result, the medical industry is now looking for cloth-based antimicrobial masks that can be used multiple times.

So, what are antimicrobial textiles? And how is the medical industry using it?

Apart from medical textiles, our exclusive report contains 3 more trends in the textile industry. If you wish to get access to the report, fill out the below form:

What are Antimicrobial Medical Textiles?

Antimicrobial medical textiles are functionally active textiles that may kill microorganisms or inhibit their growth.

These are fiber-based substrates to which antimicrobial agents are applied, including metallic and non-metallic salts such as Zinc, Silver, Copper, Chitosan, etc.

These agents are applied either at the surface or into the fibers by spraying, chemical reaction, etc. The textiles can be made of polyester, polyamide, cotton, polyester-vinyl composites, vinyl, and acrylics. The cotton segment is projected to be the largest one in antimicrobial clothing.

Antimicrobial textiles work the same way any antimicrobial soaps and sanitizers do. They attack pathogens (such as bacteria, mold, mildew, and other hazardous microbes) on a cellular level to prevent their growth and reproduction. From a perspective of pathogens, antimicrobial textiles can be – antibacterial, antifungal, and antiviral.

Applications of Antimicrobial Medical Textiles

These textiles are used in various applications ranging from households to commercial, including air filters, food packaging, health care, upholstery, hygiene, sportswear, undergarment, storage, ventilation, and water purification systems.

But as discussed, the medical industry is showing promising developments in this trend. The growing demand for antimicrobial medical textiles has resulted in many entities innovating in this domain. And today, we’ll be highlighting their growth.

This is the 2nd part of our “Medical Textile Industry trends” series. To get the complete report, fill out the form below:

BTW, here’s the 1st part- The Growing Trend in Sensor-based Smart Medical Textiles

Where is Antimicrobial Medical Textiles Heading?

These textiles tend to lose their antibacterial activity after just a few washes. Thus, one area that is catching much attention is the washability of antimicrobial clothes.

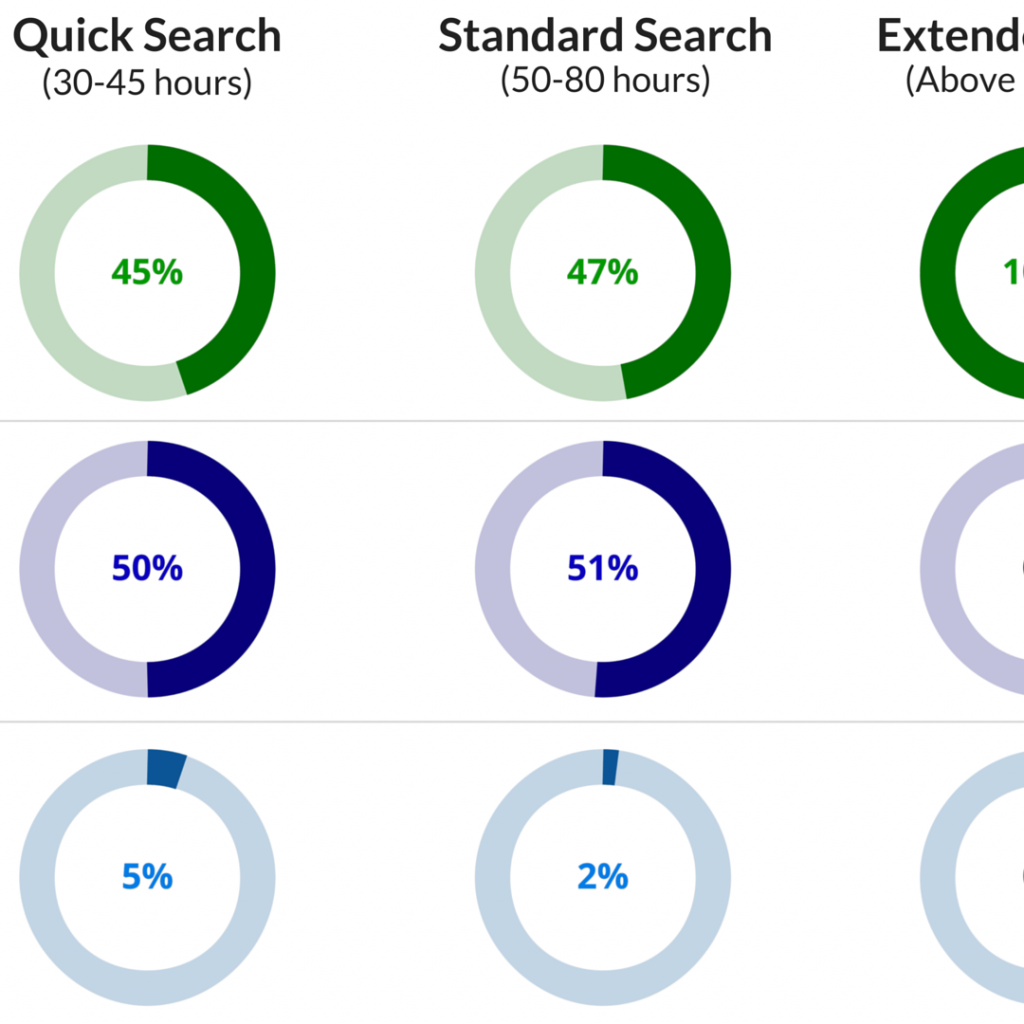

Patents published in the last five years indicate that ~25% of research is on improving the washability factor in these textiles.

Here are some of the recent innovations in Antimicrobial medical textiles-

1. Washable copper-embedded antimicrobial fabrics

Swiss Precision (a USA-based health tech apparel brand) developed a copper-embedded organic fabric. The startup weaves the virus-destroying copper into its fabrics, making them antibacterial, antifungal, and antiviral.

Testing from the SGS labs showed that it destroyed the virus completely and irreversibly.

The fabric combines the comfort, fit, and lightweight durability of organic fabrics (Cotton, Bamboo, Hemp, Linen) with the antimicrobial benefits of copper.

According to the SGS report, their Swiss Precision Eco HealthTech Fabric kills bacteria (Staphylococcus Aureus and Klebbseila Pneumonia) within 24 hours. The results remained the same even after 10 and 40 washes.

The startup will sell the product across 50,000 hospitals in the United States. Interestingly, the startup has protected its textile technology through patent filing.

2. Washable tannic acid-integrated antibacterial and anti-odor textiles

In 2022, researchers from the University of Tokyo developed a fabric with an Ag-tannic acid (TA) coating that successfully neutralizes bacteria, viruses, etc. They use polyphenol tannic acid (TA) to effectively bind the antimicrobial silver (Ag) to the fabric.

This makes it useful in hospitals and other ideally sterile environments. Also, the binding power of TA is so strong that the coated textiles tested by the researchers (on cotton, polyester, and silk) maintained their antimicrobial and anti-odor properties even after ten washes.

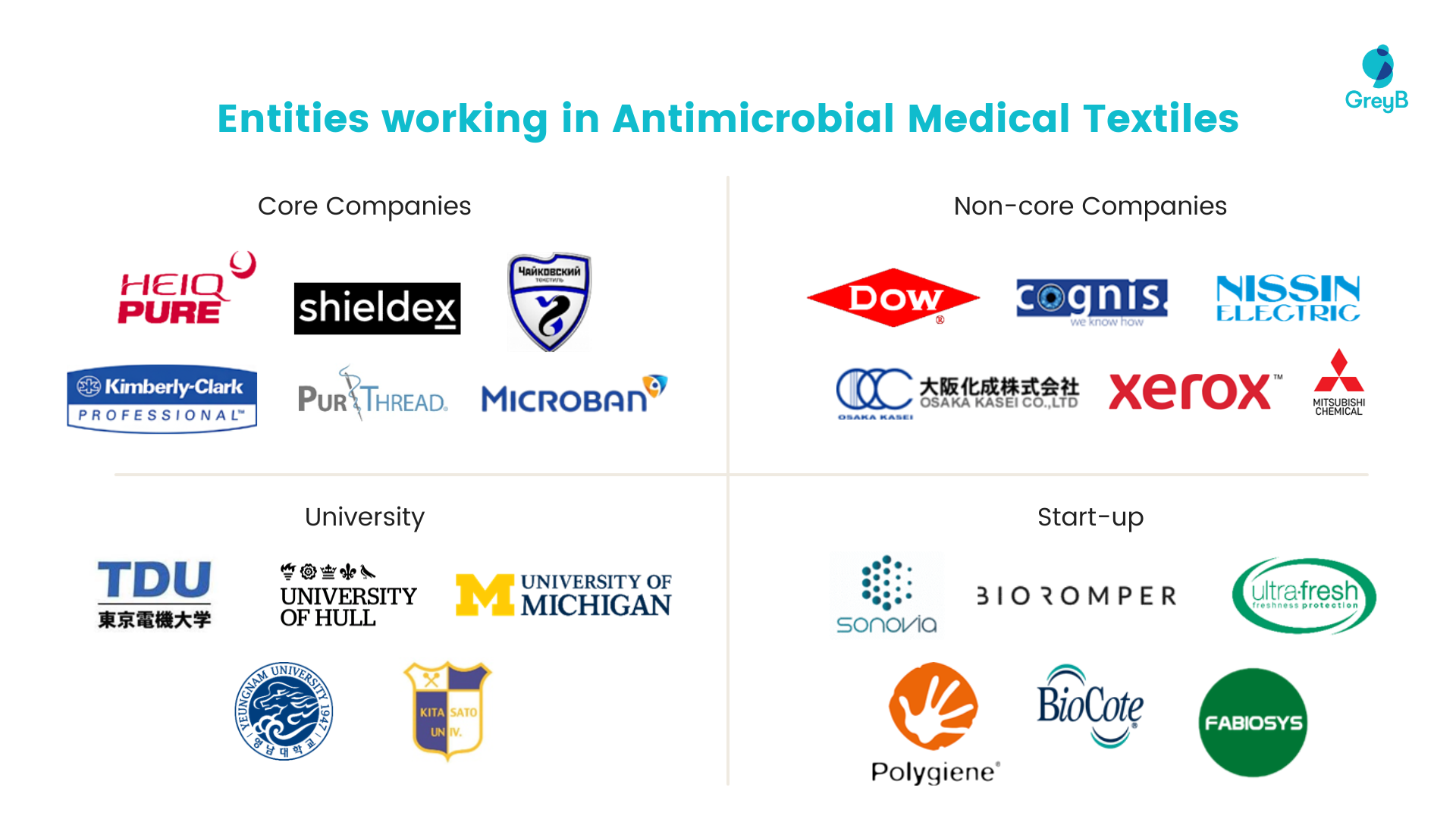

Apart from the above two, other companies and universities also work in the domain.

Who is Working on Antimicrobial Medical Textiles?

Significant Collaborations b/w non-core companies and universities in Antimicrobial Medical Textiles

Nissin Electric, a Japanese electrical equipment company, collaborated with Tokyo Denki University. The duo uses amorphous carbon to provide antibacterial properties to a gas-permeable sheet. This compound/technology could be used to make medical textile products as the patent in collaboration mentions the term “medical” textile in the embodiments.

Mitsubishi Chemicals and Osaka Kasei are the two big chemical players from Japan. Both these companies have proven capabilities in the R&D domain and have dedicated centers to support innovation.

Interestingly, we found that these entities have collaborated with Kitasato University to develop antibacterial textiles. This is reflected in their collaborative patent filings, which mentioned using quaternary ammonium halide compound to impart antibacterial properties to a fiber structure (that could be a cloth). The composition could be used to make antibacterial textiles (such as gloves, gown, mask, surgical textiles, etc.).

Could Xerox become a potential contender?

Interestingly, Xerox, a printing company unlinked to the textile industry, has a patent claiming a metal-ion polymer film with antibacterial activity.

At first, it seemed like the company might be incorporating antibacterial activities in its printing services. But our curiosity rose when we saw that in one of the claims, the company mentions that this metal-ion polymer could be incorporated with textiles to provide antibacterial activity.

This finding was astonishing as a printing company like Xerox will not launch a textile (or clothing product). And the product would have no synergies with its current business line. However, Xerox could open a licensing opportunity to others (clothing companies). They may showcase the applicability of this developed polymer film on various platforms (such as textiles).

This opens doors for textile companies to look for innovations outside their core industry and integrate them into their products.

We might see textile companies adopting open innovation shortly.

Conclusion

Despite having professional R&D capabilities and a strong presence worldwide, Mitsubishi and Osaka had to collaborate with KITASATO Institute for their antimicrobial fiber development.

This showcases that the institute might have strong technical skills and working professionals to achieve demanding tasks in this area. Other interested entities can also look for collaboration with KITASATO Institute to work out their antibacterial clothing specialization tasks.

The Antimicrobial medical textile industry is still growing. We will likely see a lot of collaborations inside and outside the domain. Watching how the trend grows in the coming years will be interesting.

Interested in finding more companies and universities you can collaborate with to innovate in the Antimicrobial textile industry?

Or Click here to read about Compostable Textiles.

Interested in more textile trends? Fill out the form to get access to the Textile Trends 2024 Report:

Authored By: Ambuj, Navjit, and Sushant, Patent Intelligence

Edited By: Nidhi, Marketing

Also Read: What to expect from the medical textiles industry in 2024?