In a survey by IBM, more than 80% of chemical industry executives said they believe that artificial intelligence will immensely impact their business within the next three years.

AI (Artificial Intelligence) is rapidly becoming an indispensable component of the chemical industry. The global AI in the chemical market is expected to be worth around $16.94 billion by 2032, with a remarkable growth rate of 31.9% from 2023. This is big news for the chemical industry, as it is at the heart of many things we use daily.

AI can make the manufacturing process more marketable and significantly reduce the company’s losses. In a chemical company’s workflow, AI can reduce prediction inaccuracies by approximately 50% compared to human forecasting. The areas where AI is used the most are R&D (74%), manufacturing (61%), forecasting and planning (47%), and risk management (58%).

This report will further explore the various applications of AI in the chemical industry and how they’re an unmistakable upgrade over the current processes.

Predictive Analytics for Chemical Synthesis

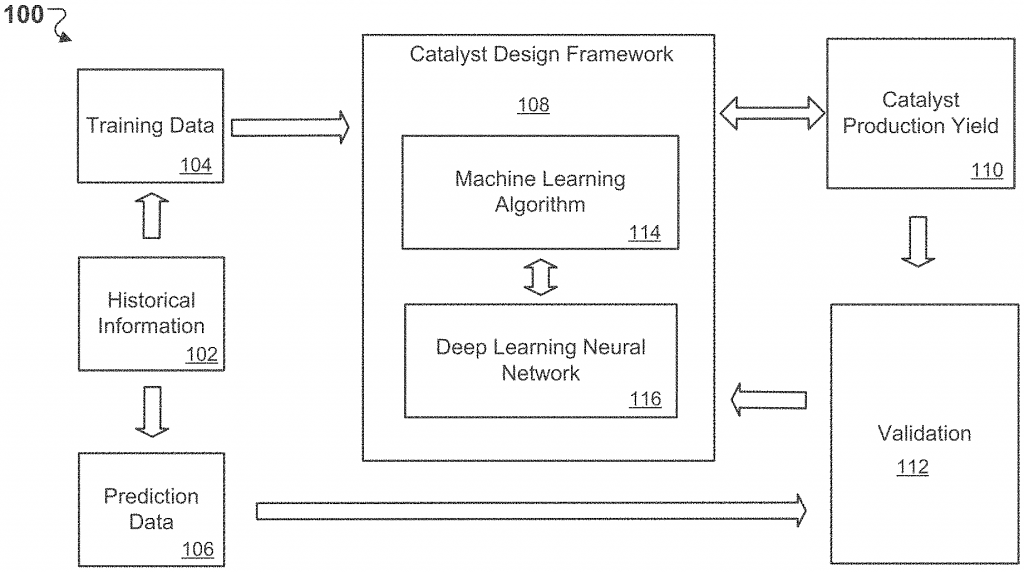

Predictive analytics, a domain where AI excels, is revolutionizing how chemical engineers understand and predict the outcomes of reactive processes. By sifting through vast datasets, AI can forecast reaction pathways and product yields, offering previously unattainable levels of precision and foresight.

An innovative patent by Chemify Ltd describes a system where AI algorithms predict the outcomes of various chemical reactions. The analysis comprises selecting suitable reactions from a pool of starting materials, selecting chemical inputs, and determining the reactivity of the given chemical and physical inputs using machine learning.

Optimized Production Processes

AI can optimize production stages, including quality control, process improvement, failure prediction/prevention, and safety monitoring. Advanced algorithms can control the variables of complex chemical reactions, ensuring consistent quality, maximizing yield, and enhancing safety by anticipating hazardous conditions.

This patent by Chevron USA Inc. outlines an AI-powered system that continuously monitors and adjusts chemical production processes. The system predicts and prevents deviations by analyzing real-time data, ensuring optimal production conditions.

Advancing Safety and Compliance

AI’s ability to predict and prevent accidents in real time by analyzing historical sensor data is indispensable for maintaining safe operations and ensuring regulatory compliance. Furthermore, with AI-enabled data analysis, companies can easily track and adjust their production to comply with the safety regulations implemented by authorities.

A patented novel approach by IBM proposes an AI system that enhances safety protocols in chemical plants. The system assesses risk factors and autonomously controls reactors using generative ML models, significantly reducing the potential for accidents and ensuring compliance with safety regulations.

Remarkable feats of AI in chemical industry sectors

Pharmaceutical Enhancement

AI algorithms streamline the drug development process, significantly reducing the trial-and-error aspect. This expedites the discovery of effective medications and enhances their safety profiles, ensuring better patient outcomes.

Innovative Plastics

The plastics industry greatly benefits from AI in creating more innovative packaging solutions. Materials developed through AI are more durable and sustainable by design while meeting consumers’ needs and safety concerns.

Energy Storage Advancements

AI is pivotal in the development of advanced batteries. It leads to improved energy storage solutions essential for the longevity and safety of consumer electronics and electric vehicles.

Cosmetic Formulation Optimization

In cosmetics, AI reduces the guesswork in product formulation, paving the way for optimized beauty products that align with consumer expectations and regulatory standards.

Longevity of Construction Materials

AI tools can predict the lifespan of construction materials, making the building a safer, more resilient infrastructure. This predictive capacity ensures the longevity and sustainability of construction projects.

Conclusion

While AI in the chemical industry points to a future where precision, efficiency, and innovation are at the forefront, it highlights a concurrent need for skilled professionals with AI and chemical expertise.

The transition to AI-centric methodologies requires careful consideration of a company’s workforce implications, ethical concerns, and regulatory responsibilities.

The patents mentioned in this report only exemplify a fraction of AI’s potential applications within the chemical sector. As this integration deepens, the chemical industry can look forward to an era where its oldest challenges are met with new, cleaner, and infinitely more creative solutions.

Many of your competitors may already be exploring AI for their businesses. Researching their strategies could take months, but GreyB’s competitor analysis tool can give you a headstart within 30 seconds!

Step confidently into the upcoming quarter armed with a meticulously crafted and highly competitive strategy.

If you have a specific question, please submit it using the form below, and our experts will respond to you.

Authored By – Sahil Kapoor, Product Development Team

Edited By – Hemanth Shenoy, Marketing