In March this year, a group of engineers successfully made a delectable cheesecake from scratch on a 3D printer. Until now, most 3D food printing was only possible for uncooked products. Columbia Engineering’s research, on the other hand, used lasers to cook the cheesecake as it prints. (Source)

As the world becomes increasingly fascinated by personalized experiences and cutting-edge technology, the future market for 3D food printing appears exceptionally promising. The ability to cater to individual tastes, deliver precise nutrition, and bring culinary fantasies to life makes this emerging field as a game-changer for the food industry.

However, it is just the beginning. Due to the advantages and features of 3D printing, its future market seems lucrative.

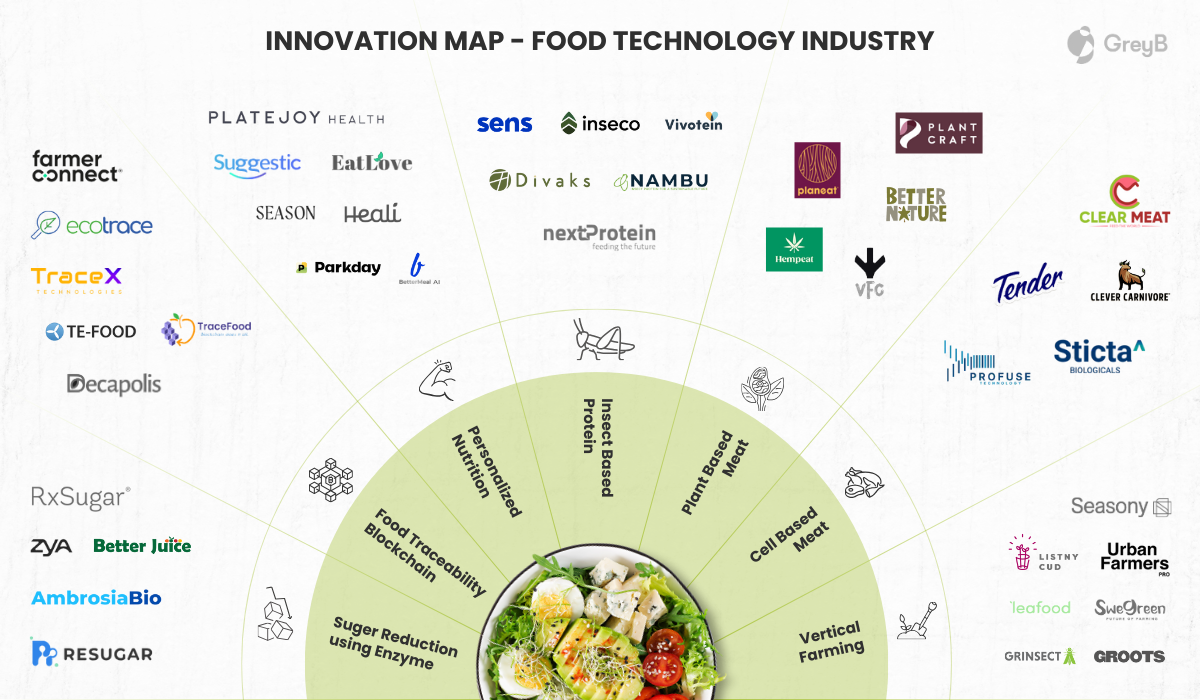

Explore the recent innovations in food technology! Learn about leading startups creating insect-based proteins, plant-based meat alternatives, and more. Get your hands on our Food Tech Startup Report to uncover the latest trends shaping the future of food.

Fill out the form below and request your copy today!

Market Growth

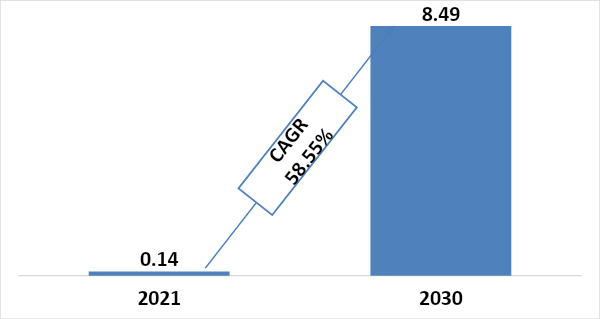

In 2021, the 3D food printing market generated a revenue of $140 million. However, experts predict a remarkable surge in its growth, with expectations reaching an astounding $8.49 billion by 2030. This extraordinary expansion is projected to occur at an approximate compound annual growth rate (CAGR) of 58.55% throughout the forecast period.

The North American region is set to witness the highest 3D food printing market share. The region’s expansion is fueled by increased awareness of nutrient consumption and high disposable income. Therefore, regional market players are developing 3D-printed meals to tackle emerging health issues.

Furthermore, the 3D Food Printing market in the Asia Pacific is also expected to grow speedily during the forecast period. (Source)

Global 3D Food Printing Market Size during 2021-2030 ($Billion)

Despite its many advantages, it has some challenges that need to be ironed out before this technology becomes a household name. One of which is the challenge of ensuring print accuracy while maintaining the appropriate texture. Meanwhile, sanitation needs to avoid contamination and establish shelf life also rank high on the list of challenges.

Fortunately, some startups in this domain are actively innovating to make 3D Food Printing better. Therefore, we have compiled a list.

Startups Working on 3D Food Printing

1. Natural Machines

Natural Machines is a Spanish company that developed the Foodini, a 3D food printer designed for professional and home kitchens. The Foodini can print various foods, including pasta, pizza, and chocolate. One only needs to load the printer with the ingredients needed for the recipe.

The ingredients, however, need to be pureed and loaded into food-grade capsules, which are then inserted into the printer. Then, the user must select the desired recipe from the touchscreen interface, and the printer extrudes the ingredients in layers, building up the final product.

Source: Natural Foods

One of the advantages of the Foodini is that it allows for precise control over the amount and placement of ingredients. This can be especially useful in professional kitchens, where consistency is important. Additionally, it can be programmed to produce complex shapes and designs, adding a unique touch to dishes. The Foodini is also designed to be easy to use. The touchscreen interface is intuitive, and the printer comes with pre-programmed recipes that users can select from.

Additionally, the printer is also highly customizable, allowing users to create new recipes and experiment with different ingredients. No wonder it has worked with some big names in the industry, such as Nestle, Pepsico, Whitsons Culinary Group, etc.

Most importantly, Foodini’s plastic components are constructed of PolyCarbonate or PolyPropylene, which are both food-grade and BPA-free. (Source)(Source)(Source)(Source)

The company has raised 5.4 Million in funding to date.

2. Nūfood

NuFood is a 3D food printing technology that uses a unique printing method to create customized and nutritious food items. This technology is based on a patent-pending process involving high-pressure extrusion to create intricate designs using various food materials.

The NuFood system includes a 3D printer, a software program, and a place for loading food materials. The software creates a digital design model to be printed. It is then loaded into the printer, and the food material in the high-pressure extruder. It is then precisely used to control the amount of extruded material.

As the printer prints the design, the extruder nozzle moves in a predetermined pattern, building up the design layer by layer until the final object is complete. The high-pressure extrusion process allows a wide range of food materials to be used in printing. They can include food products with high viscosity or that are difficult to print using traditional 3D printing methods.

One of the unique features of the NuFood system is the ability to print customized and nutritious food items. The software program allows users to adjust the nutritional content of the printed food item, such as adjusting the amount of protein or fiber in the material. This makes the NuFood technology particularly useful for creating specialized diets or catering to individual dietary requirements. (Source)(Source)

3. BeeHex

BeeHex, a NASA spin-off company, is a 3D food printing technology that allows users to create intricate and customizable food designs. The company aims to create a 3D Food Printer system to personalize food for astronauts on long-duration space journeys.

BeeHex’s 3D decoration technology also enables bakers to manufacture adorned cookies, cakes, cupcakes, and other items quickly and precisely. This technology is based on a patent-pending process that uses pneumatic pressure to extrude food materials through a nozzle and create a wide range of food items.

The system includes a 3D printer, a software program, and space for various food materials. The software program is used to create a digital model of the design to be printed, which is then loaded into the printer. The next step is to stock food material in a pneumatic pressure system. That is then used to control the amount of material that is extruded.

As the printer prints the design, the pneumatic pressure system forces the food material through the nozzle, building the design layer by layer until the final object is complete. The nozzle moves in a predetermined pattern, allowing complex designs to be printed quickly and easily.

One of the unique features of the BeeHex system is the ability to customize the printing process to achieve different textures. For example, the system can print foods with different densities, allowing for various textures such as crunchy, chewy, or soft. Additionally, the system can print multiple colors of food materials, allowing for even more creative possibilities. (Source)(Source)(Source)(Source)

4. byFlow

byFlow is a 3D food printing company that allows users to create food designs according to their tastes. This technology is based on a unique modular design that allows users to easily swap out extruder heads and print a wider range of food materials.

The byFlow system comprises three main components: a 3D printer, a software program, and designated compartments for various food materials like chocolate, dough, and purees. The software program plays a crucial role in crafting a digital model of the desired design, which is subsequently transferred to the printer. The interchangeable extruder head of the printer is responsible for loading the specific food material and meticulously regulating the precise amount of material extrusion.

During the printing process, the extruder head of the byFlow system follows a pre-defined pattern, gradually constructing the design by adding layers until the final object is fully formed. Thanks to its modular design, users can effortlessly replace the extruder heads, enabling the utilization of diverse food materials throughout the printing procedure.

The company has introduced the byFlow Studio, an online platform for 3D Food Printing, which includes an easy-to-use Design Tool for producing personalized forms, a library of standard designs, recipes, and a support area. (Source)(Source)(Source)

In 2019, byFlow announced a collaboration with Eindhoven-based manufacturer VDL Group to produce and assemble its byFlow 3D printers. Soon after, Verstegen Spices & Sauces of Rotterdam announced that it would be the first company to adopt byFlow’s Focus 3D Food Printer with ready-to-use fillings. Verstegen was previously supplied byFlow with gourmet food printing fillings, including beetroot and cardamom flavors. (Source)

In Oct 2021, it showcased its patented technology for (personalized) 3D Chocolate Printing.

5. 3Desserts Graphiques

3Desserts Graphiques, based in France, provides 3D printers for chocolate. The company creates, manufactures, and sells CE-certified 3D food printers.

The L’Impressionnante printer from 3Desserts Graphiques is a digital pastry bag customizing desserts or sculptures’ decorations. The printer belongs to a new generation of 3D printers that use Stäubli’s unique robotic technology. (Source)(Source)

Data from Statista indicates that the meat substitutes market revenue is approximately $10.15 billion in 2023. The market can grow 10.58% CAGR annually till 2028. Plant-based meat analogs are here to stay, and we spotted these two 3D-printed meat companies making headlines.

6. Revo Foods

Revo Foods creates plant-based seafood using a 3D food printing system. The company aims to prevent overfishing and relieve pressure on the marine ecosystem without missing out on delicious “fish” meats.

The company claims it has saved over 18,900 fish as of August 2023 and produced up to 86% less CO2 than regular salmon.

One of their recent products, the world’s first 3D-printed salmon filet, reached store shelves in September 2023. The Filet uses mycoprotein from filamentous fungi, pea proteins, plant oils, and algae extracts, delivering an authentic, meat-like texture. Its plant-based ingredients grant this product a three-week shelf life, a noticeable upgrade from regular salmon products.

Funding and Finances

Revo Foods has raised $5.86M over 6 rounds of funding. Their most recent funding round was on January 25, 2023, where they raised $1.63 million from Eurostars Programme, FFG, and Vinnova. The company is privately held and may not publicly disclose its financial information, such as quarterly and annual revenues.

Patents and IP Portfolio

Revo Foods GmBH holds only one patent. It’s for their 3D print head design. They applied for a patent for their 3D food print head with a cooling die and an extrusion nozzle in August 2021, pending approval as of date.

Author’s note – 3D Food Printing is one of the key trends of Food Tech in 2023. Interested in more trends? Fill out the form to get the report with all 10 Food Tech Trends:

7. Redefine Meat

Redefine Meat, an Israeli food startup, makes 3D-printed, plant-based beef substitutes. Their patented 3D-printed beef composition combines soy & pea protein, chickpeas, beetroot, nutritional yeasts, and coconut fat. It resembles flank steak, which is also known as bavette.

The company unveiled its first 3D-printed plant-based product, Alt-Steak, in August 2023. This product comprises the company’s own set of formulated plant-based ingredients: Alt-Muscle, Alt-Fat, and Alt-Blood.

Their whole-cut meats appeal to many customers through the 150 restaurants they partner with in Israel. Their products require far less refrigeration and have a longer shelf life. These analogs have no cholesterol content, making them more accessible to health-conscious people.

Furthermore, the company claims its 3D-printed meat decreases environmental impact by 95% while being cheaper than traditional meats.

Funding and Finances

Redefine Meat has raised over $170 million as of January 2023 through 4 funding rounds. The company’s annual expenses and finances aren’t publicly disclosed.

Patents and IP Portfolio

Redefine Meat holds the following patents in its portfolio.

| Patent Number | Title |

| AU2020211093A1 | Meat analogues and methods of producing the same |

| WO2021095034A1 | Whole muscle meat substitute and methods of obtaining the same |

| US20230114348A1 | Packed texturized protein units and uses thereof |

| WO2023084526A1 | Food analogues preparation method and products |

| WO2022079717A1 | Meat analogue and method of producing the same |

| CA3181152A1 | System and method for fabrication of a three-dimensional edible product |

| US20230001638A1 | Support apparatus |

| WO2023031915A1 | An edible hydrogel, method of production, and uses thereof. |

| WO2023037376A1 | Whole-muscle meat analogues with fluid accommodating spaces and methods of producing the same |

| BR112021014510A2 | MEAT ANALOGS AND PRODUCTION METHODS THEREOF |

| BR112021014510A2 | Análogos de carne e métodos de produção dos mesmos |

Collaborations

Selina

Redefine Meat and Selina, a lifestyle and experiential hospitality brand, launched one of the world’s largest plant-based hospitality collaborations. This initiative is part of Selina’s goal of shifting menus to greater plant-based options, with 100% of Selina’s menus available plant-based.

Giraudi Meats

Redefine Meat announced a major strategic partnership with Europe’s largest high-end meat importer, Giraudi Meats. This partnership will help Redefine Meat expand across dozens of countries.

Wholesaler Partners in the UK

Redefine Meat is accelerating its UK distribution with eight wholesaler partners to meet demands. Its UK wholesalers now span national and regional brands, including Albion Fine Foods, Braehead Foods, Brakes, Classic Fine Foods, Elite Fine Foods, Food Republic, Forest Produce, and Zebra Plant Based.

Production in the Netherlands

Redefine Meat has set up production in the Netherlands and joined various other international food innovation companies, including Meatless Farm and Beyond Meat.

Conclusion

3D food printing technology is expected to play a significant role in the food industry in the upcoming years, given its ability to produce customized food products that cater to individuals’ specific dietary needs and preferences. The possibilities are endless, from athletes seeking tailored nutrition plans to patients requiring specialized meals. Additionally, in the realm of space exploration, 3D food printing holds the key to customized sustenance for astronauts.

As this technology continues to evolve, it presents a compelling opportunity for big companies and innovative players to carve out their space in the market. By staying ahead of the curve and gaining comprehensive insights into the activities of key industry players, you can position yourself as a frontrunner in this emerging landscape.

Contact us now to unlock the untapped potential of 3D food printing and seize the immense opportunities that lie ahead.

Next Read: 5 Innovation Trends Shaping the Food Tech Industry

Authored By: Vipin Singh, Marketing