While wood paper offers convenient and familiar protection for packaging, its environmental impact casts a long shadow. Wood-based paper is problematic for two main reasons: deforestation and sustainability. While it doesn’t inherently seem problematic, how it’s sourced and produced can raise concerns.

These are increasingly important concerns on a global scale, prompting several recent laws and regulations to tackle these issues.

As per the EU Deforestation Regulation, companies introducing beef, soy, coffee, timber, and other commodities to the EU market must guarantee that their sourcing is free from deforestation, with no land clearance after December 2020.

This regulation also applies to wooden packaging but with some exemptions. The determining factor is whether the wood is discarded after its intended use.

These concerns & regulations are driving companies to explore alternative materials for paper production, known as non-wood paper.

Non-Wood Paper: A Sustainable Alternative to Wood Packaging

Non-wood paper packaging emerges as a sustainable alternative, addressing the environmental limitations of wood-based materials. It offers a lower ecological footprint derived from various plant sources, such as bamboo, hemp, and agricultural residues.

Agricultural wastes are considered by low raw materials price, moderate quality, and abundant raw materials after the harvesting season, such as rice, wheat straw, corn stalk, and sugarcane bagasse.

Bamboo, reeds, grass, and papyrus are naturally growing plants. These materials regenerate faster than trees, reducing the impact on deforestation and biodiversity. Non-wood paper also tends to require less energy and chemicals in processing, leading to a reduction in carbon emissions and pollution.

Kenaf is the third category of non-wood fiber and the most important pulp and paper industry resource.

Non-tree paper packaging is available in various forms, including paper, cardboard, and molded products. These materials can be tailored to meet the specific requirements of different industries, ensuring effective product protection while minimizing environmental impact.

What stops non-wood paper from getting widespread adoption?

Adopting non-wood paper on a wider scale encounters several challenges, categorized into economic, technical, and market-related factors. These challenges must be addressed to facilitate industries’ and consumers’ broader acceptance and use of non-wood paper products.

1. Cost and Economic Viability

The high production costs associated with non-wood paper packaging pose a significant challenge to its widespread adoption. These materials are often more expensive than their traditional wood-based counterparts, primarily due to the limited economies of scale and the need for specialized equipment and facilities.

Non-wood raw materials are slow to drain and, consequently, cause problems in the paper machine. Because of this, the paper machine cannot be run at high speeds, so dropping the production and the cost for paper made from nonwood fibers is higher. Machines running wood fibers are sometimes as fast as three times faster than those running non-wood fibers like straw.

2. Adoption

When a company considers adopting non-wood paper, it encounters complex challenges, notably cost and supply. Materials like bamboo or hemp are often pricier due to limited suppliers and the industry’s smaller scale, leading to potential supply chain issues and elevated product costs.

Customer awareness and perception significantly impact this transition. Many might not recognize the benefits of non-wood paper and possibly view it as inferior to wood-based alternatives, affecting purchase decisions and the company’s brand image.

Further, technological shifts are also daunting, as transitioning to non-wood paper production may necessitate substantial investment in new machinery or modifications to existing infrastructure, posing financial and operational challenges.

3. Quality

Companies considering non-wood paper products face significant quality perceptions and realities challenges. Non-wood paper often has a different texture, durability, and printability than traditional wood-based paper. This variation can raise doubts about its ability to meet the high-quality standards for applications like office printing, packaging, and specialty papers.

Consumers used to the reliable performance of wood-based paper may be wary of non-wood alternatives, questioning their ability to perform equally well in printers without jams or to match the feel and longevity of the traditional paper.

For applications like packaging and labeling, Non-wood paper must be robust enough to withstand the rigors of shipping and handling while maintaining its aesthetic appeal. It should also be compatible with various types of adhesives and finishes. Compromises in paper quality could result in labels that peel off, fade, or are easily damaged during transit.

Similarly, the primary concerns for stationery products like notebooks and office paper are printability and durability. Non-wood paper used in these applications must accept ink well without bleeding or feathering and be sturdy enough to handle regular handling, writing, and erasing. Inferior-grade non-wood paper might result in poor print clarity and paper that tears easily, reducing its usability and appeal to consumers.

These critical quality factors influence purchasing choices and the broader market acceptance of non-wood paper products.

4. Supply Chain and Logistics

Adopting non-wood paper products presents significant supply chain challenges for companies. Non-wood sources like bamboo, hemp, or agricultural residues are not as widely used or standardized as wood pulp, leading to a less developed supply infrastructure. This can result in limited availability and higher volatility in supply and prices, making it difficult for companies to secure a consistent and reliable source of raw materials.

Additionally, the geographic distribution of non-wood raw materials can pose logistical challenges. These materials might be available in regions not traditionally associated with paper manufacturing, necessitating the establishment of new supply chains that span different countries or continents. This expansion requires significant investment in logistics, including transportation, storage, and handling facilities, which can be a substantial financial burden.

The lack of established suppliers and processors for non-wood materials can lead to quality control and standardization challenges. Companies might face difficulties ensuring that non-wood paper products meet consistent quality specifications, which is crucial for maintaining product reliability and customer trust.

Moreover, integrating non-wood materials into existing production processes may require modifications to equipment and supply chain operations, leading to additional costs and complexities. Companies must assess whether their current supply chain infrastructure can accommodate these changes or if new investments are necessary.

Due to these challenges, companies find it difficult to access non-wood paper suppliers, especially regarding their technological competence.

Major Challenges: Supplier Selection and Integration

Finding suppliers is not as difficult as assessing suppliers’ integration in new product development.

Research has shown that supplier involvement increases competence and access to technology, innovation, and resources and mitigates risks in new product development.

While working with suppliers has benefits, selecting suppliers without proper due diligence can lead to many challenges.

With an unreliable supplier, a buyer can lock in with the supplier and its technology. Further, the integration can be complex and critical for a seamless supply chain. So, knowing a supplier’s technological competence and integrating it into new product development can become a major solution for companies.

To solve this challenge, a framework can help companies choose suppliers, determine their technological competence, and ensure seamless integration.

A Framework to Assess Suppliers and Solving Integration Challenge

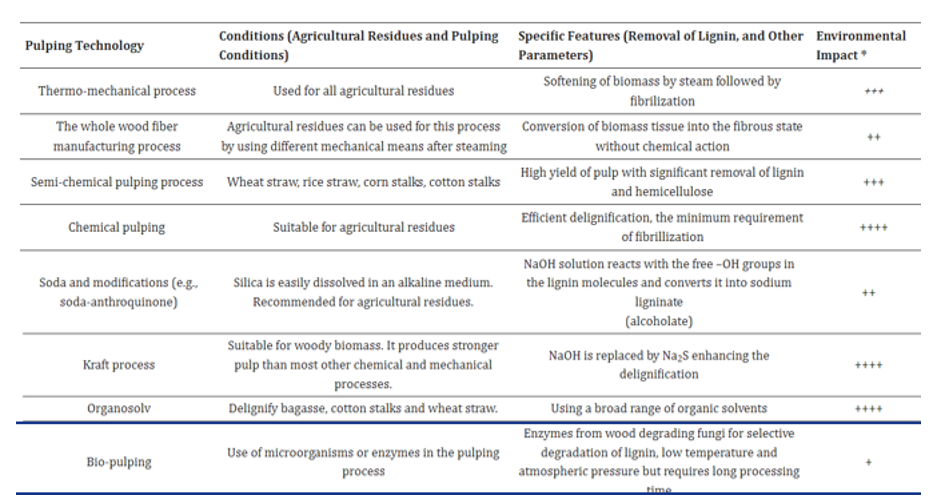

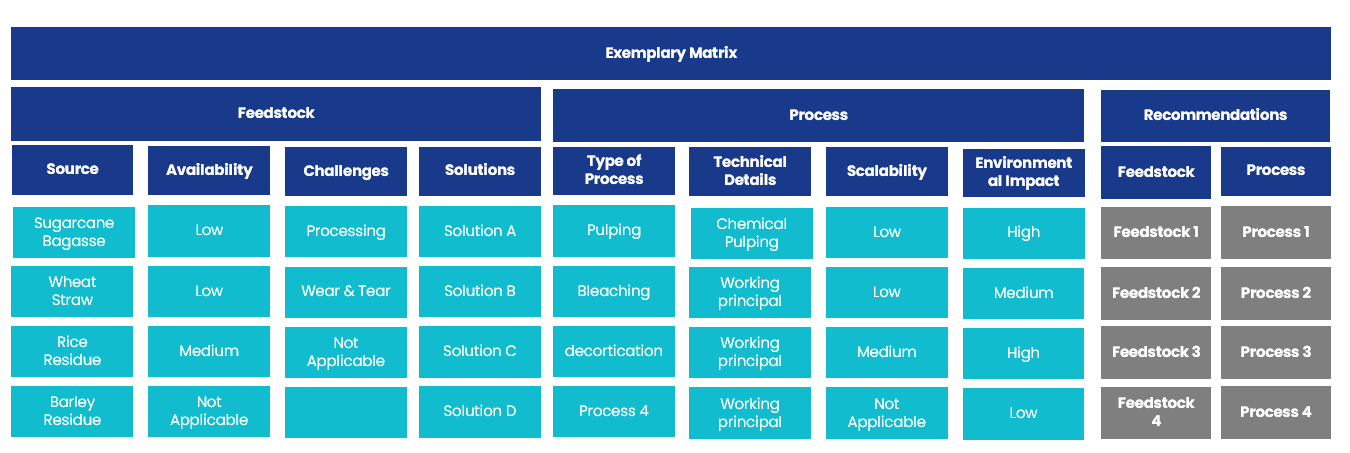

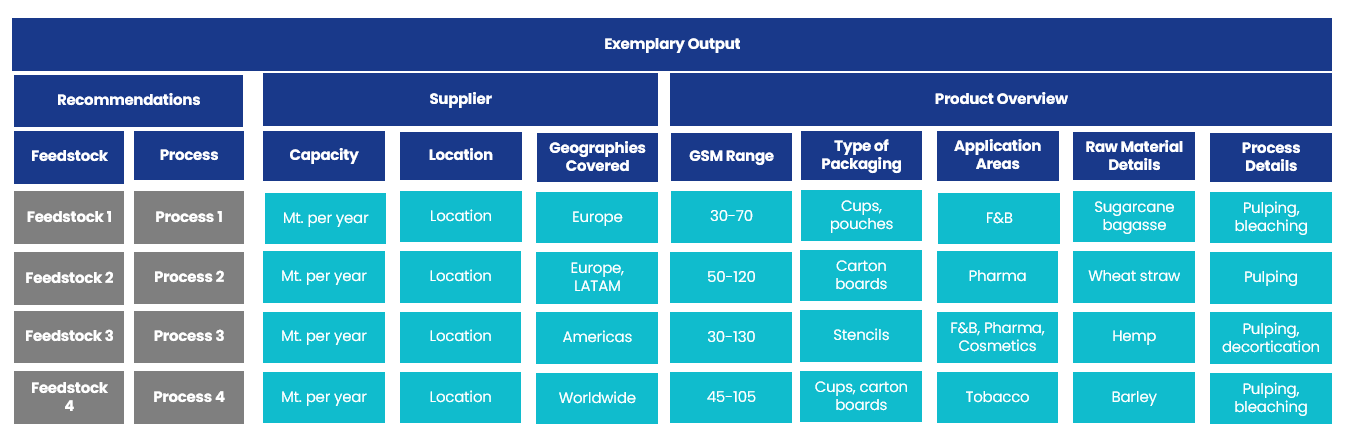

The framework operates on two principal variables: feedstock and processes, aiming to discern optimal suppliers. Each feedstock identified undergoes comprehensive analysis to extract vital data, including the source of feedstock, its availability, challenges encountered during processing, and potential solutions to these challenges. A list of suppliers utilizing specific feedstocks is compiled, focusing on emerging feedstocks and those gaining widespread adoption.

Next, the framework examines the steps in turning these materials into products. This includes looking at the methods used, their issues, and how they affect the environment.

With all this information, the framework determines which processing method is best for each material. A special chart, or matrix, helps lay out all these details clearly, showing which combinations of materials and methods work best.

Using this chart, it’s easier to identify the top suppliers based on the right mix of materials and processing methods. This chart acts as a guide, showing which suppliers are recommended based on their use of materials and methods. This way, the framework helps make smart choices about which suppliers to use, focusing on those that meet the specific needs and are environmentally friendly.

The suppliers can be provided based on additional requirements, such as for applications such as packaging, stationary, cigarette papers, custom packaging, etc.

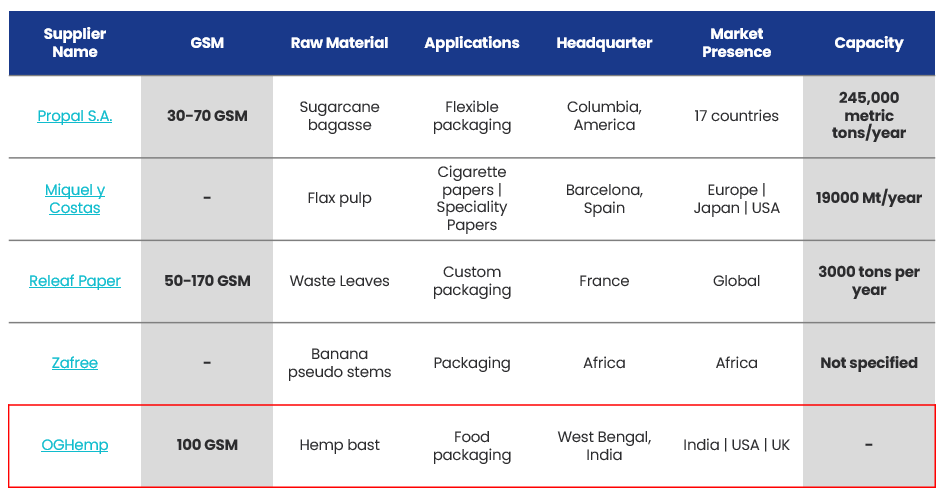

For example, the table below offers 5 suppliers based on different raw materials offering different applications and information like market presence and production capacity.

Request the prelim report to learn more about the framework for supplier analysis:

Conclusion

Non-wood paper holds significant potential across various industries. Its adoption could lead to substantial changes in industries like packaging, printing, and even baby food packaging, where specific quality standards are paramount.

However, challenges such as cost and availability, consumer perceptions, technological requirements, and supply chain integration pose hurdles to its widespread adoption.

Addressing these challenges requires a multifaceted approach, including advancing production technologies, enhancing supply chain stability, shifting consumer and industry attitudes through education, and demonstrating the benefits of non-wood paper. Policy support and investment in research and development could also play crucial roles in overcoming these obstacles.

If these challenges are addressed, non-wood paper will revolutionize many industries by providing a more sustainable, versatile, and potentially cost-effective alternative to wood-based paper.

Its adoption will contribute to environmental sustainability by reducing reliance on forest resources and spark innovation in product development and supply chain management across various sectors.

Need an in-depth understanding of the industry’s landscape?

Fill out the form to submit your request:

Authors: Abhiti Labroo, Kartik Chikara, and Vikas Jha, Solutions.