The Battery recycling industry is rapidly growing to prevent environmental degradation as the world transitions to electric vehicles and other battery-powered devices. In the efforts to go green and be an entirely circular economy, the EU has passed new regulations regarding the manufacturing and recycling of batteries.

One of the most promising areas of innovation in battery recycling is the development of new technologies that can recover more valuable materials from batteries. However, it is not without its challenges, such as the high cost of processing, the environmental impact of traditional methods, and the lack of battery recycling infrastructure.

Startups are playing a significant role in this domain by working on these challenges to make battery recycling more efficient, environmentally friendly, and accessible.

This article covers the top 9 battery recycling startups after weighing the pros and cons of their innovative technologies.

So, let’s dive right in.

1. Ascend Elements

| Website | https://ascendelements.com/ |

| HQ | Massachusetts, United States |

| Total Funding Amount | $921.9 Million |

| Top Investors | Oman Investment Fund, TRUMPF Venture, SK ecoplant, Fifth Wall, At One Ventures, Hitachi Ventures, Gly Capital Management, Doral Energy-Tech Ventures, Mirae Asset Capital. |

| Innovative Tech | Offers a patented Hydro-to-Cathode™ Process to recycle and convert old batteries into sustainable battery materials that perform on par or better than new batteries. |

Which Innovative technology is the startup using for recycling batteries?

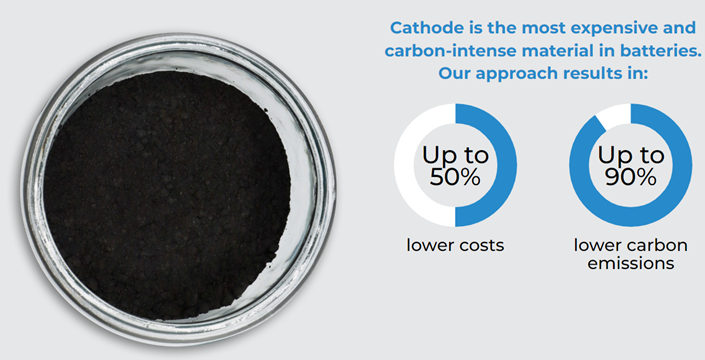

Patented Hydro-to-Cathode™ Process – Ascend Elements’ patented Hydro-to-CathodeTM direct precursor process improves material performance and value. This technique simplifies recycling and converts old batteries into sustainable battery materials that perform as well as or better than new batteries.

Unlike traditional processes that leach metals from old battery materials, this unique process leaches away contaminants. Furthermore, it does that while maintaining the valuable metals in the solution and avoiding additional steps in the recycling flow.

Furthermore, traditional lithium-ion recycling technologies entail numerous steps that consume a significant amount of energy. They also concentrate on recovering intermediate compounds to further sell on commodity markets. The Hydro-to-Cathode direct precursor synthesis is more efficient and sustainable, returning higher-level materials to the supply chain. Life cycle assessment techniques developed at Argonne National Labs showed that Ascend Elements’s process significantly reduced environmental impacts across the board compared to conventional approaches.

According to Eric Gratz, Ph.D., Co-founder and CTO of Ascend Elements, “When it comes to recycling used lithium-ion batteries and transforming those critical elements into new cathode material, it doesn’t matter what type of lithium-ion battery is recycled. The battery chemistry at the start of the process does not impact the type of new cathode material we can make from it. If the feedstock is a lithium-ion battery, we can transform it into the latest cathode type.”(Source)

Hydro-to-Cathode™ Process

Comparison of Hydro-to-Cathode™ Process to Other Processes

What are the collaborations made by the startup?

In 2023, Ascend Elements and Honda Motor Co., Ltd. partnered to procure recycled lithium-ion battery materials for Honda electric vehicles in North America. Since 2021, Ascend Elements has been recycling spent lithium-ion batteries for American Honda Motor Co. The new collaboration was a critical step toward establishing a closed-loop supply chain for recovered battery materials such as lithium, nickel, and cobalt. It leveraged the efficiencies and environmental benefits of Ascend Elements’ unique Hydro-to-Cathode direct precursor synthesis.

According to Mike O’Kronley, CEO of Ascend Elements, “Honda is aiming for ‘zero environmental impact’ by 2050, and sourcing recycled battery materials for its electric vehicles is a huge part of that. We’re honored to continue our strategic relationship with Honda in North America.” (Source)(Source)

In 2022, Ascend Elements and EcoPro Group collaborated and signed a memorandum of understanding to develop, qualify, and integrate recycled battery materials into EcoPro’s cathode products. Ascend Elements used their novel Hydro-to-Cathode process to convert black matter into a sustainable, high-performance precursor that rivals cathode materials derived from pure metals.

Which Awards have been received by the startup?

The company has received several awards, such as Fast Company’s 2023 World Changing Ideas Award, the 2023 Edison Awards (Silver), The 2023 Cleanie Awards (Silver), the 2023 Automotive & Transportation Merit Awards (Gold & Silver), 2021 NEVY Award by the New England Venture Capital Association, among others. (Source)

2. Redwood Materials

| Website | https://www.redwoodmaterials.com/ |

| HQ | Nevada, United States |

| Total Funding Amount | $2.8 Billion |

| Top Investors | US Department of Energy, Ford Motor, Valor Equity Partners, Emerson Collective, Baillie Gifford, Canada Pension Plan Investment Board, Franklin Templeton Investments, Breakthrough Energy Ventures, Goldman Sachs Asset Management, Climate Pledge Fund. |

| Innovative Tech | Offers a closed-loop, domestic supply chain for recycling lithium-ion batteries and provides large-scale sources of local anode and cathode materials to U.S. cell manufacturers. |

Which Innovative technology is the startup using for recycling batteries?

Electrification is expected to increase lithium-ion consumption by more than 500% by 2030. The supply chain is unprepared to support that expansion. To meet industry demand, Redwood is developing a closed-loop, domestic supply chain for lithium-ion batteries. It will include collecting, refurbishing, recycling, refining, and remanufacturing sustainable battery materials to expedite the elimination of fossil fuels. The company will utilize large-scale sources of local anode and cathode materials derived from recycled batteries for this. (Source)(Source)(Source)

Closed-Loop Battery Recycling Solution

Redwood Materials Battery Recycling Program

What are the collaborations made by the startup?

In 2022, Redwood Materials and Toyota partnered on electric vehicle battery collecting, remanufacturing, recycling, and delivering battery materials. They will be developing a closed-loop battery solution through this collaboration. Redwood Materials has concentrated on testing and recycling Toyota batteries and developing end-of-life paths for the original hybrid electric vehicles. The companies intend to grow into additional sectors across North America, such as battery health screening and data management, remanufacturing, and battery material supply.

According to Christopher Yang, Group Vice President of Business Development at Toyota, “We are excited to be working with Redwood Materials to identify solutions for our electrified powertrains at the end-of-life that contributes to our vision of creating a sustainable, circular battery ecosystem.” (Source)(Source)

Redwood Materials also collaborated with Rotary International to recycle outdated rechargeable devices in 2022. A dozen Stanford professors and Ph.D. students worked with Redwood on a lifetime analysis of lithium-ion battery recycling. Furthermore, these two companies held community events throughout the United States to educate, engage, and develop accessible recycling channels for people to recycle their household lithium-ion batteries and devices. (Source)(Source)

In the same year, 2022, Redwood Materials also collaborated with Volkswagen Group of America to recycle all the batteries from Volkswagen and Audi electric vehicles. Now, Redwood operates directly with Volkswagen Group of America’s over 1,000 dealers to recover, safely package, transport, and recycle end-of-life electric car battery packs from Volkswagen and Audi vehicles. Its end-to-end process has reclaimed the value of those lithium-ion batteries and transferred it to cell manufacturing partners in the United States, making EVs and American manufacturing more sustainable and reasonable.

According to JB Straubel, Founder and CEO of Redwood Materials, “Redwood and Volkswagen Group of America share a vision to create a domestic, circular supply chain for batteries that will help improve the environmental footprint of lithium-ion batteries, decrease cost and, in turn, increase access and adoption of electric vehicles.” (Source)(Source)(Source)

In 2021, Redwood Materials announced a strategic partnership with Ford Motor Company. Both companies collaborated to establish a closed loop for battery recycling and a local supply chain for crucial battery ingredients. The Ford and Redwood approach started with implementing battery recycling into Ford’s American battery production plan. It also placed scrap from battery production and batteries nearing the end of life, into the battery supply chain. Thereby, following this process, they lowered costs, reduced environmental impact, and ensured a vital battery material supply that Ford required to continue ramping up electric vehicle production. (Source)(Source)

Patents In Their Portfolio

Redwood Materials has 1 registered patent to its name.

3. Li-Cycle

| Website | https://li-cycle.com/ |

| HQ | Ontario, Canada |

| Total Funding Amount | $1 Billion |

| Top Investors | US Department of Energy, Glencore, LG Chem, LG Energy Solution, Koch Strategic Platforms, Koch Strategic Platforms, Neuberger Berman Group, Mubadala Capital Ventures, Moore Strategic Ventures, Carnelian Energy Capital Management. |

| Innovative Tech | Offers patented and environmentally friendly lithium-ion battery recycling technologies and employs a wet-chemistry process. |

Which Innovative technology is the startup using for recycling batteries?

Spoke and Hub TechnologiesTM – Li-Cycle implements a patented and environmentally friendly lithium-ion battery recycling technique to offset any harm caused by vital storage devices. The company recycles all LIBs in two stages, including much bigger EV batteries, and recovers up to 95% of the materials. Its Spoke and Hub Technology employs a wet-chemistry process rather than intense heat, resulting in minimum wastewater and low emissions.

Spoke & Hub Technologies, developed by the company, employs a combination of reliable mechanical size reduction and hydro-metallurgical resource recovery specifically suited for lithium-ion battery recycling. Li-Cycle uses a patented shredding technique to treat LIB material at its Spoke facilities. The LIB material is then turned into three main product streams at Li-Cycle’s Spokes: polymers, copper/aluminum, and a substance known as ‘black matter,’ which comprises precious metals such as lithium, nickel, and cobalt. (Source)(Source)

Spoke & Hub Technologies – Li-Cycle

What are the acquisitions made by the startup?

In 2021, Li-Cycle acquired Peridot Acquisition Corp. This acquisition cost roughly $580 million, which the business utilized to promote its lithium-ion battery resource technology globally.

According to Ajay Kochhar, Co-Founder and CEO of Li-Cycle, “As the electric vehicle revolution continues to ramp up, we believe our technology will be critical for supporting the growth of e-mobility globally while ensuring sustainability and resource efficiency.” (Source)(Source)

What are the collaborations made by the startup?

Li-Cycle and VinES Energy Solutions signed a comprehensive and extended long-term recycling partnership agreement in 2023. According to the agreement, Li-Cycle will become VinES’ strategic and preferred recycling partner for Vietnamese-sourced battery materials beginning in 2024. The agreement also anticipates the possible development of a specialized Spoke near VinES’ manufacturing facility, consistent with its objective of increasing recycling capacity in tandem with client demand. Furthermore, using its North American Spoke network, Li-Cycle will facilitate the processing of VinES’ material.

The startup also formed a strategic alliance with KION Group in 2023. According to the agreement, the environmentally friendly recycling of lithium-ion batteries is expected to start in the second half of this year. This new relationship assures KION Group that the most significant materials from the lithium-ion batteries it supplies can be recovered. Li-Cycle will begin recycling in its new plant in the Magdeburg area, and it also has plans to expand into other countries, including France.

According to Henry Puhl, Chief Technology Officer of the KION Group AG, “With this strategic partnership, we are taking an important step towards the circular economy that we want to implement for our products. The collaboration with Li-Cycle will further strengthen our position in the area of sustainability.” (Source)(Source)

In 2023, Li-Cycle signed a Letter of Intent with Glencore for a joint study to develop a European recycling hub in Portovesme, Italy. The Portovesme Hub would use recovered battery content to manufacture crucial elements such as nickel, cobalt, and lithium. The Hub will use Li-Cycle’s cutting-edge hydro-metallurgical technology to become Europe’s largest producer of sustainable battery-grade products.

In 2022, Li-Cycle and Vines Energy Solutions established global recycling cooperation. The firms investigated worldwide recycling solutions for VinES and VinFast as part of their new collaboration. This new collaboration is expected to assist VinES and VinFast in developing a closed-loop battery supply chain to improve their environmental goals and contribute to the global electric revolution through green mobility solutions. Additionally, Li-Cycle’s patented and sustainable lithium-ion battery recycling solutions, such as its Spoke & Hub solutions, are a perfect fit in terms of size and scope for VinES and VinFast’s current and planned manufacturing capacities. (Source)

In 2021, Li-Cycle collaborated with Arrival to develop a sustainable and circular EV battery supply chain in the United States and Europe. They teamed up on leadership initiatives and R&D efforts to increase lithium-ion battery recycling in the US and Europe, as well as the efficiency of the EV battery supply chain. Furthermore, Li-Cycle’s revolutionary commercial lithium-ion battery recycling methods turn end-of-life batteries from Arrival’s EV fleets into battery-grade material that creates new batteries for their new vehicles.

According to Kunal Phalpher, Chief Strategy Officer of Li-Cycle, “This strategic commercial partnership demonstrates our ability to meet emerging new customer demands as we continue to scale our proven, commercial lithium-ion recycling technology globally.” (Source)

In 2021, Li-Cycle partnered with Ultium Cells LLC to recycle up to 100% of the product leftover from manufacturing battery cells. Due to the novel recycling technique, Ultium Cells can recycle battery elements such as cobalt, nickel, lithium, graphite, copper, manganese, and aluminum. Additionally, 95% of these materials were used in manufacturing new batteries or related businesses. (Source)

Which Awards have been received by the startup?

The Company has received multiple awards since its inception, such as the 2023 Bloomberg New Energy Finance (BNEF) Pioneers Award, the 2021 BIG Innovation Award, and the Award for Circular Economy Project of the Year 2020 (10th annual BusinessGreen Leaders Awards). (Source)(Source)(Source)

4. EnergyX

| Website | https://energyx.com/ |

| HQ | Texas, United States |

| Total Funding Amount | $524.5 Million |

| Top Investors | General Motors, The Global Emerging Markets Group, Helios Capital, Helios Capital, Mirza Canada, Weclikd. |

| Innovative Tech | Offers LiTAS™, an innovative lithium extraction technology that reduces the amount of energy, cost, and time needed to extract lithium. |

Which Innovative technology is the startup using for recycling batteries?

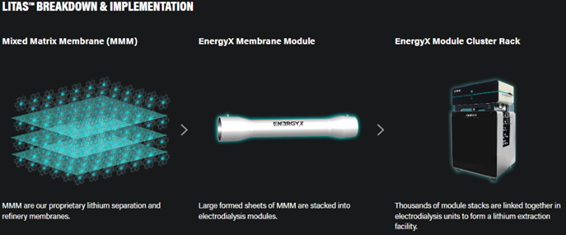

Lithium Ion Transport and Separation (LiTAS™) – EnergyX’s range of lithium selective and processing processes is known as Lithium Ion Transport and Separation (LiTAS™). It employs mixed matrix membranes to boost lithium recovery for old and new Li-brine resource producers. It is the company’s patented combination technology, which includes lithium-selective electrodialysis membranes. Furthermore, EnergyX has invented and patented scalable implementation methods with LiTAS™ to reduce costs and manufacture the market’s lowest-cost lithium.

While present lithium technology goes down in one or more areas, LiTAS™ is significantly more effective than any other technology on the market. The unique technique separates lithium from other contaminants to produce a rich lithium chloride solution. Furthermore, EnergyX has also created a nanotechnology membrane capable of near-instant separation and good recovery rates. (Source)(Source)

Lithium Ion Transport and Separation (LiTAS™)

What are the collaborations made by the startup?

GM Ventures led a $50 million Series B fundraising round in EnergyX in 2023, and the company has engaged in a strategic collaboration to enhance its lithium extraction and refinery technologies. The agreement aims to increase the availability of lithium, a vital material for EV batteries, in North America by utilizing EnergyX’s revolutionary approach to maximize efficiency while enhancing sustainability for GM’s fast-scaling EV production. (Source)(Source)

In 2020, EnergyX and ProfMOF formed a partnership to promote the use of Metal-Organic Frameworks (MOFs), a relatively new class of nanotechnology materials that can be used to develop renewable energy, large-scale lithium-ion production, and battery storage. The collaboration between EnergyX and ProfMOF emphasizes the prospects offered by metal-organic frameworks and how they pave the road for sustainable development through scientific innovation. Furthermore, MOFs are also being used by EnergyX in their breakthrough Lithium-Ion Transport and Separation Technology (LiTAS) to lessen the environmental impact of lithium mining.

“MOFs have properties that we have never seen before, and EnergyX is partnering with the MOF world leaders to harness these powers. By creating more lithium and energy storage, thus reducing the intermittency of renewable power, we can have a great impact.”

– Teague Egan, CEO of EnergyX (Source)(Source)

In 2020, EnergyX and Orocobre Limited inked a Letter of Intent (LOI) to collaborate on applying direct lithium extraction (DLE) technologies in the lithium mining sector to promote sustainable development and innovation. Rising global demand for electric vehicles and a more efficient energy system has resulted in a projected exponential growth in lithium demand. This development has enabled firms like EnergyX to introduce cutting-edge DLE technology to make lithium extraction more efficient, sustainable, and cost-effective.

According to Teague Egan, CEO of EnergyX, “Lithium demand is set to increase 10x over the next 10 years; it will be an integral part of a global transition towards a sustainable future. EnergyX is thrilled to be collaborating with Orocobre in developing an even more lithium extraction process, and we look forward to making DLE technologies the new norm.” (Source)(Source)

5. Aqua Metals

| Website | https://aquametals.com/ |

| HQ | Nevada, United States |

| Total Funding Amount | $5.5 Million |

| Top Investors | Undisclosed Angel investors. |

| Innovative Tech | Offers its patented technology to recycle old lithium-ion batteries in a clean, cost-effective, and fundamentally non-polluting manner. |

Which Innovative technology is the startup using for recycling batteries?

Li AquaRefining™ Technology-Aqua Metals began operations in a dedicated prototype recycling facility, employing its patented Li AquaRefining™ technology to actively extract battery minerals from wasted lithium-ion batteries using this novel technology.

This technology is a closed-loop, low-temperature recycling system capable of recovering all essential minerals in ‘black mass,’ a ground-up mixture of the metals in lithium batteries. The company uses electricity to power this efficient process, significantly lowering pollutants and toxic waste associated with battery recycling. Additionally, the technology recycles old lithium-ion batteries in a clean, cost-effective, and fundamentally non-polluting manner by using renewable electrons as the reagent rather than chemicals or high heat. (Source)(Source)(Source)

Li AquaRefining™ Technology

What are the acquisitions made by the startup?

In 2017, Aqua Metals, Inc. bought Ebonex IPR Limited of the United Kingdom for 123,776 shares of Aqua Metals’ regular stock and $100,000 in cash as Ebonex’s innovative materials have the potential to revolutionize lead acid chemistry by increasing energy density, cycle life, and charging speed.

According to Dr. Stephen R. Clarke, Chairman and CEO of Aqua Metals, “We believe there is a multi-billion dollar market opportunity for advanced lead acid batteries in upcoming automotive and stationary battery applications. Working with this technology will allow us both to advance our nano-structured lead-based materials and leverage synergies with Ebonex materials.” (Source)(Source)

What are the collaborations made by the startup?

In 2023, Aqua Metals, Inc. and 6K Energy collaborated to create the next generation of low-carbon battery materials and a long-term deal for 6K Energy’s PlusCAM cathode material manufacturing unit. The collaboration began with a non-recurring engineering (NRE) arrangement to further develop low-carbon technologies for converting essential metals, first virgin and then recycled, into battery-grade cathode active material (CAM) precursors. Both companies are working to create a future in which sustainable, high-performance lithium batteries are manufactured in the United States using domestically produced resources.

According to Steve Cotton, President & CEO of Aqua Metals, “Our commitment to pioneering low-carbon, closed-loop battery recycling powered by electricity aligns perfectly with 6K Energy’s groundbreaking sustainable cathode manufacturing, and our partnership signifies a major step towards U.S. leadership in the next generation of net-zero battery materials and technologies.” (Source)(Source)

In 2021, Aqua Metals, Inc. and LINICO Corporation inked a collaboration agreement to partner on future research and development. Thus, both firms’ growth into lithium-ion battery recycling strengthened, and both companies’ commitment to advancing best-in-class technology designed to recycle lithium-ion batteries cost-effectively and sustainably was strengthened. Aqua Metals and LINICO intended to source the required lithium-ion feedstock from multiple sources, including electric car battery suppliers, battery manufacturing scrap, and end-of-life cells.

By working together, Aqua Metals and LINICO plan to provide a cost-effective and environmentally responsible solution instead of solely relying on mining strategic metals from out-of-country sources that can result in harsh environmental and social costs.

– Steve Cotton, President & CEO of Aqua Metals (Source)(Source)

In 2021, Aqua Metals, Inc. collaborated with BASF to supply electrolytes, engage commercially, and investigate technical advancements to increase AquaRefining performance. BASF provided the primary supply of Aqua Metals’ electrolytes for all new licensee plants and was the licensees’ preferred supplier partner for continuing electrolyte needs. Both organizations have agreed to unify their business activities to give an integrated service to their clients. BASF specifically provided AquaRefining to its existing and prospective battery recycling customers, and Aqua Metals included BASF products in every first deployment and system fill.

Steve further added, “This partnership will also leverage BASF’s global reach to help offer AquaRefining to applicable companies within their global client base as well as work with us in the future to explore ways to enhance the electrolyte for improved AquaRefining performance.”(Source)(Source)

Which Awards have been received by the startup?

The company has received several awards, such as Sustainable Technology Award (2016 IChemE Awards), Platts Metals Awards 2017, and San Francisco Business Times Technology and Innovation Award 2017, among others. (Source)(Source)(Source)

6. Lithion Recycling

| Website | https://www.lithiontechnologies.com/ |

| HQ | Quebec, Canada |

| Total Funding Amount | $102.8 Million |

| Top Investors | GM Ventures, Fondaction, IMM Investment, Sustainable Development Technology Canada. |

| Innovative Tech | Offers hydro-metallurgy technology to recover battery-grade materials. |

Which Innovative technology is the startup using for recycling batteries?

Hydro-metallurgy Technology – Lithion Recycling Inc. has key materials extraction and purification solutions that combine creative applications of current processes with new operations for maximum efficiency. The results are battery-grade strategic materials that cell and battery manufacturers can use to create new lithium-ion batteries. The company’s technologies allow it to recover over 98% of the minerals concentrate, and the battery packs are crushed to create its distinctive hydro-met-ready critical minerals concentrate (Black Mass).

Lithion created an efficient and cost-effective recycling technique for lithium-ion batteries. The procedure allowed for the recovery and treatment of around 95% of battery components, allowing battery producers to close the loop on the battery life cycle. Additionally, the company’s unique hydro-metallurgy technology is used to recover battery-grade lithium, cobalt, and nickel, as well as graphite and manganese, from the concentration of the essential mineral. (Source)(Source)

Lithion’s Hydro-Metallurgy Technology

What are the collaborations made by the startup?

In 2022, Lithion Recycling Inc. and General Motors Co. signed a strategic collaboration agreement to achieve a circular battery ecosystem using Lithion’s innovative battery recycling technology. GM and Lithion teamed to validate Lithion’s recovered battery materials for use in creating new batteries and the possible acquisition of battery materials.

Lithion will begin commercial recycling operations in 2023, based on data from its industrial-scale demonstration plant, completed in January 2020.

According to Benoit Couture, President and CEO of Lithion, “Working with GM marks a key step in Lithion’s commercial development by enabling a cost-effective and sustainable circularity in the EV battery industry. This partnership underscores our commitment to enable the transition to a low-carbon economy amidst the fight against climate change.” (Source)(Source)

In 2022, the startup agreed to an exclusive business right to use its lithium-ion battery recycling technology on the Korean market with IS Dongseo Company Ltd. (ISD). This is the first in a series of collaborations Lithion hopes to complete in the coming years to use its cutting-edge, eco-friendly technology on global markets. It enabled ISD to provide an ecologically friendly and cost-effective recycling solution in Korea, closing the loop on battery materials.

The demand for lithium-ion battery recycling has been increasing exponentially, and Lithion’s commercial plants offer scalable capacity to accommodate market growth. The company intends to launch a large-scale international deployment by granting licenses to important operating partners.

Benoit Couture further shared, “This is a very exciting milestone in our quest for providing sustainable, cost-effective and locally-adapted solutions for recycling lithium-ion batteries around the globe.” (Source)(Source)

Lithion Recycling Inc. and Hyundai Canada announced a partnership in 2021 to retrieve and recycle high-voltage batteries from some of its Hybrid, Plug-in Hybrid, and Electric vehicles, aiming to boost the sustainability of its electric vehicle manufacturing cycle. Hyundai was the first Canadian automaker to formalize a service agreement with Lithion.

According to Benoît Couture, This service agreement will validate an economical and innovative technology that considerably reduces the carbon footprint compared to incumbent technologies and mining. (Source)(Source)

Which Awards have been received by the startup?

The company received three prizes at the ESTim Gala of the Chamber of Commerce of Eastern Montreal. Lithion was awarded the Orchid Award, which is given to an organization in appreciation of its continued efforts, dedication, leadership, and excellent participation in the growth and economic and social development of Montreal’s eastern suburbs, in addition to others. (Source)

Patents In Their Portfolio

The granted patent pertains to Lithion Recycling Inc.’s innovative hydrometallurgy technology for safely dismantling lithium-ion batteries and producing battery-grade materials. This patent allows Lithion to utilize its unique recycling process for twenty years, ensuring its ability to recover valuable materials from lithium-ion batteries sustainably. (Source)

7. American Battery Technology Company

| Website | https://americanbatterytechnology.com/ |

| HQ | Nevada, United States |

| Total Funding Amount | $84.2 Million |

| Top Investors | US Department of Energy, United States Advanced Battery Consortium, U.S. Department of Energy Advanced Manufacturing Office |

| Innovative Tech | Offers closed-loop battery recycling technique for recovering, purifying, and recycling the batteries |

Which Innovative technology is the startup using for recycling batteries?

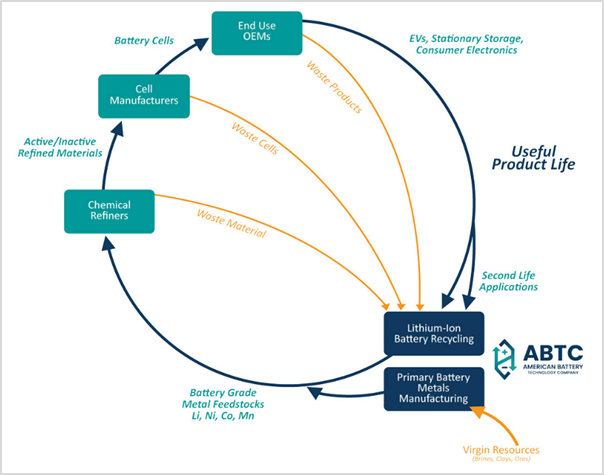

Closed-Loop Battery Recycling Process – The American Battery Technology Company (ABTC) invented the closed-loop battery recycling technique. The technology separates and recovers essential materials from end-of-life batteries, purifying them to the same or higher quality criteria than conventional minerals supplied from virgin mining operations. The procedure is optimized and efficient, able to process materials relatively quickly.

This integrated battery recycling system was built by the ABTC team using a systematic de-manufacturing methodology. The business has created a ‘de-manufacturing’ technique to remove metals and minerals from used batteries.

Their recycling technique combines a programmed deconstruction process with a targeted hydro-metallurgical, non-smelting process that breaks down battery packs into modules, modules into cells, and cells to sub-cell components. It then strategically separates and sorts those sub-cell components. This approach reduces waste, conserves natural resources, reduces air pollution, improves operating efficiencies, increases material recovery rates, and captures battery-grade materials without losing quality(Source)(Source).

Closed-Loop Battery Recycling Technique

What are the collaborations made by the startup?

In 2023, American Battery Technology Company (ABTC) signed an agreement to get a move-in-ready, commercial-scale battery recycling facility in the Tahoe-Reno Industrial Centre (TRIC), Nevada, to expand operations of its lithium-ion battery recycling technologies.

The agreement was reached primarily due to increased demand following the passage of the Inflation Reduction Act (IRA) in the autumn of 2022, which included mechanisms to incentivize electric vehicle manufacturers and consumers to purchase electric vehicles (EVs) that use battery metals manufactured in the United States. Ryan Melsert, CEO of ABTC, even said, “We are excited to be able to capitalize on this opportunity to accelerate the first commercial-scale implementation of our integrated lithium-ion battery recycling technologies.” (Source)

In 2022, it joined the Suppliers Partnership for the Environment (SP). ABTC, in collaboration with SP, will support the automobile industry in reducing environmental impacts through innovative, sustainable practices, technologies, and resources. (Source)

Since 2021, the ABTC technology team has also been at the National Centre for Applied Research (NCAR) incubator facilities at the University of Nevada Reno (UNR). The ABTC team partnered with UNR teachers and staff on their present government funding and drafting applications for current grant solicitations. This collaboration gave ABTC access to UNR’s superior facilities, equipment, knowledge, and students.

According to University President Brian Sandoval, “This partnership with American Battery Technology Company showcases the role of NCAR and the impact of Nevada’s Knowledge Fund support, and it allows us to offer new and exciting experiences to our students.” (Source)(Source)

8. Ruicycle

| Website | http://www.ruicycle.com/ |

| HQ | Guangdong, China |

| Total Funding Amount | CN¥400 Million ($56.91 Million) |

| Top Investors | Hidden Hill Capital, Hua Ventures, Legend Capital, Hanhui Investment Management, China Guangfa Bank |

| Innovative Tech | Utilization of lithium battery cascades, material regeneration, and the recycling of new materials |

Which Innovative technology is the startup using for recycling batteries?

The company focuses on the core technologies, such as the utilization of lithium battery cascades, material regeneration, and the recycling of new materials, to develop the technologies of zero-pollution battery treatment, automatic safe battery crushing, and high-yield recycling, which are necessary to increase the production scale of lithium batteries. (Source)

What are the collaborations made by the startup?

In 2022, Ruicycle (Chinese name: Hengchuang Ruineng) collaborated with GLP Hidden Mountain Capital to enable an industrial chain partnership. The company announced the completion of a B+ round of funding totaling more than 100 million yuan led by Yinshan Capital. This GLP affiliate then led to the company authorizing an investment agreement to build a lithium battery material recycling and dual material precursor production project with an annual output of 10,000 tonnes in August 2022.

For example, Hidden Hill Capital was looking ahead to new technologies, new models, and new trends in the industry. Still, after relying on the resources of GLP’s smart logistics ecosystem, it utilized the synergistic effect of its ecological system through its profound industrial heritage and high ecological resource potential in this collaboration with Hengchuang Ruineng. (Source)

In 2022, it signed a planned cooperation agreement with Shenzhen Bus Group to develop the recycling industry of modern energy vehicle decommissioned batteries in Shenzhen and contribute to the double carbon target. Both firms integrated resource advantages in the fields of new energy and transportation, actively explored and carried out research and development, testing and application of power battery chain application scenarios, and accumulated data and experience to achieve the goal. This aided in the establishment of a power battery recycling network in Shenzhen as well as the construction of a power battery recycling demonstration facility. (Source)

In 2020, the startup collaborated with China Putian to successfully recycle the first batch of around 200 used power batteries in buses in Shenzhen. The company went to the site with professional crews from Shenzhen Bus Group and China Putian Group to disassemble the retired bus’s battery pack.

The entire operation was carried out in an insulated atmosphere, which not only assured the safety of the personnel but also made later transportation and storage of the battery easier. The skilled team discovered, sorted, and built the battery cells and modules and completed scientific and battery safety evaluations. Hence it developed a new model for the utilization of decommissioned power lithium batteries. (Source)

Which Awards have been received by the startup?

The company has received the ‘2022 Upstream and Renewable Resources Enterprise’ of the Golden Globe Award for High-tech Lithium Batteries. (Source)

9. Green Li-ion

| Website | https://www.greenli-ion.com/ |

| HQ | Singapore |

| Total Funding Amount | $35.5 Million |

| Top Investors | Envisioning Partners, Monterey Bay Economic Partnership, Banpu NEXT, Equinor Ventures, EDP Renewables, ISDonseo (Korea), Decarbonization Consortium, TES (Singapore), DPI Energy Ventures, SOSV. |

| Innovative Tech | Offers technology that re-manufactures lithium-ion batteries into battery-grade materials |

Which Innovative technology is the startup using for recycling batteries?

Green-HydrorejuventationTM Technology – The battery-grade material is produced using Green Li-ion battery recycling technology called Green-Hydrorejuventation Technology which is a set of modules deployed and licensed to recyclers, battery OEMs, and cathode manufacturers. These modules are the size of a small house that can be moved by truck. Furthermore, the company created the GLMC-1, a proprietary multi-cathode processor that recycles wasted lithium-ion batteries straight into 99.9% pure cathodes, faster than current recycling procedures and at a lower cost. It increases the overall sustainability of its application by employing components derived entirely from recycled lithium-ion batteries. (Source)(Source)

Green Li-ion’s Green-Hydrorejuventation Technology

Green Li-ion obtained a $20.5 million pre-series B fundraising round from TRIREC, Banpu NEXT, and Equinor Ventures in 2023. Furthermore, it has created a prototype of its GLMC technology and anticipates beginning commercial production in the first half of 2023, and this technology can handle 4-6 metric tonnes of waste batteries daily.

According to Sinon Vongkusolkit, CEO of Banpu NEXT, “We’re excited with this strategic partnership with Green Li-ion to address the environmental impact of end-of-life batteries in order to support circularity, quench global warming, and maximize the reuse of energy storage and resources.” (Source)(Source)

Future Outlook

The future outlook for the battery recycling industry is positive as the demand for batteries continues to grow, and so does the demand for battery recycling. This will create opportunities for startups to develop new technologies and business models that can help to meet this demand.

Here are some of the trends that are likely to shape the future of battery recycling:

- The development of new technologies that can recover more valuable materials from batteries.

- The increase in patent filings by large OEMs like Tesla, BMW, Hyundai, GM, etc., in the battery recycling domain.

- The development of new business models for battery recycling that are more profitable and sustainable.

- The increasing regulation of battery recycling will drive the development of more environmentally friendly practices.

If you want to keep up with the upcoming trends in battery recycling startups to carve a niche out for yourself in this domain, just fill out the form below, and we will keep you updated with all relevant information.

Authored by: Vipin Singh, Marketing

Edited By: Moksha Jain, Marketing

Next Read: Grow your EV battery recycling business using Patents