The COVID-19 pandemic resulted in a massive rise in the usage of medical personal protection equipment (PPE) worldwide. An exponential demand and the single-use nature of these products have led to the problem of littering. In addition, most of these products are made from plastics (such as polypropylene and polyethylene terephthalate) and have thus become a matter of concern.

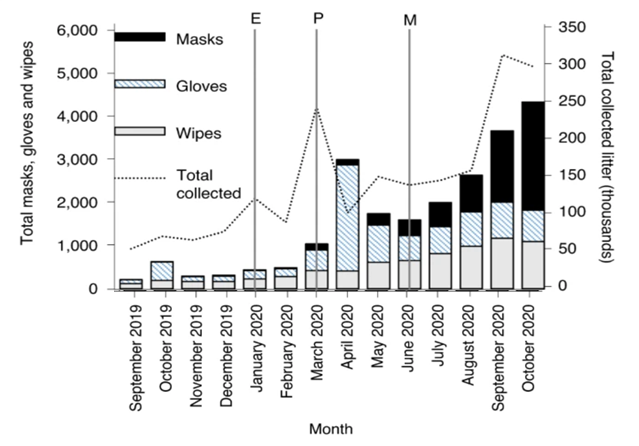

Here’s how the pollution patterns caused by these PPE equipment look.

The litter caused by gloves increased from 0.2% to 2.4%, and the waste generated by wipes rose from 0.2% to 0.6%. The trash caused by masks showed the most significant change since the pandemic, resulting in an 84-fold increase.

To tackle this problem, the medical industry is increasingly working on Compostable textiles.

These textiles are easy to dispose off after use without causing any harm to the environment and help in society’s sustainability goals. Hence, compostable textiles are of great use in medical applications.

Governments across the globe (such as UK. USA, Japan, etc.) have started initiatives (funding, campaigns, etc.) to increase focus toward compostable PPE kits. For example, The National Research Council of Canada (NRC), in collaboration with Environment and Climate Change Canada (ECCC), Health Canada (HC), and Natural Resources Canada (NRCan), are seeking solutions for the manufacture of compostable disposable surgical masks and respirators to be used by healthcare workers.

Interested in Textile Industry Trends in 2024? Fill out the form to get access to the report:

Applications of Compostable Textiles

Compostable medical textiles can be used in diapers, masks, gloves, PPE kits, and other single-use and throw clothing. However, looking at the stats from World Economic Forum, masks, and gloves seem to be the application areas with greater interest.

Since these will be the application areas where most players target their resources, we’ll dive deep into compostable medical textiles.

This is the third and final part of our medical textile trends report. Fill out the form below to get the complete report directly to your inbox.

What are the focus research/innovation areas in compostable medical textiles?

Looking at the recent patent filings, we found that research is scattered across a range of challenges (such as replacing raw material with natural substitutes, ways to recycle efficiently, improving biodegradability & mechanical properties, etc.). Out of these challenges, the areas which are being focused on more are:

1. Improving mechanical properties:

Research has shown that adding compostability to textiles degrades their mechanical properties. About 30% of the patents we analyzed are trying to address this issue. Some entities working on this concept are Kingfa Science and Technology, Planet Home, University of West England, Lodz University, etc.

2. Upcycling PPE waste:

The other trend we saw is to convert the waste from these single-use medical textiles to some other useful form (such as pellets, petroleum, etc.). Around 35% of the patents (out of the analyzed set) discuss various ways to upcycle medical textile waste. In addition, many universities, such as CSIR-National Chemical Laboratory, IIT Ropar, Hochschule Niederrhein University of Applied Sciences, and some companies (such as Reliance, Barco One, etc.) are also exploring this area.

Some recent innovations in compostable medical textiles

1. Biodegradable medical clothing with improved mechanical properties

Guangdong Kingfa Science and Technology Co Ltd (a China-based supplier of advanced materials) is developing a biodegradable medical clothing kit. The company has filed a patent application in China for the same- CN114633535A.

The clothing material is developed using multiple layers (an outer layer made of a biodegradable film, an inner layer made of all-cotton spun lace, and a water-soluble adhesive positioned between the inner layer and the outer layer). This biodegradable film comprises polyglycolic acid, butylene terephthalate, and polybutylene succinate. These compounds provide the clothing with biodegradable characteristics, mechanical properties, and softness. Further, the company has also researched increasing this film’s water vapor barrier property by adding polybutylene succinate and polybutylene adipate.

2. Converting PPE medical waste into petroleum products

In 2022, Cornell University started working on a PPE processing system for waste PPE kits. The main focus of this research is using “Pyrolysis” to convert PPE medical waste back into chemical form (such as petroleum). This crude petroleum is then recycled into various fuel forms, which can be used again.

The proposed PPE processing system reduces 31.5% of total fossil fuel use and 35.04% of total greenhouse gas emissions compared to the incineration process. It also avoids 41.52% and 47.64% of entire natural land occupation from the landfilling and incineration processes. (Source)

Who is working on compostable medical textiles?

Significant collaborations in Compostable Medical Textiles

Precision Textiles & SHG use plant-based raw materials to develop biodegradable PPE kits and face masks. The duo claims these PPE kits and masks create 56% fewer carbon emissions.

Kruger, a Canadian corporation that manufactures publication papers, tissue, lumber, and other wood products & Pulp Moulded have collaborated to use recycled/virgin fibers to develop biodegradable and disposable masks.

Do big players have a chance to dominate the market?

We looked into the patent filing trend of the top six companies in compostable medical textiles. It turns out only 3M and Ansell are working on the trend.

Interestingly, various startups and small companies have led this transformation towards more sustainable medical textiles.

When the big players start researching in this domain, they’d require talent with specific experiences in developing these types of textiles. This can result in many collaborations with startups, companies, and universities that have successfully researched and demonstrated compostability characteristics in their innovations.

Future Outlook of Compostable Medical Textiles

Currently, various innovations are targeting to bring compostability factor into medical textiles. However, they are limited in number (despite the constant backing for the demand for these textiles by governments, institutes, hospitals, etc.). Less than 500 research paper publications have been published since 2018, and less than 1000 patent filings since 2018.

One of the reasons for this could be that the funding for these innovations started only recently. In fact, we saw that most of the startups and universities were able to get funding after 2021, and it has been on the increase for the last two years.

These funding initiatives indicate some serious research efforts are underway for developing these textiles.

We believe that, in the upcoming year, we‘ll see a boom in the volume of innovations in compostable medical textiles.

In the first two parts of the medical textile trends, we discussed Sensor-based smart medical textiles and Antimicrobial medical textiles.

Fill out the form to get access to all 4 Textile Trends in a single pdf:

Authored By: Ambuj, Navjit, and Sushant, Patent Intelligence

Edited By: Nidhi, Marketing

Also Read: What to expect from the medical textiles industry in 2024?