Packaging industry innovation trends focus predominantly on sustainable and technological advancements. People are more aware of the environment today, more concerned about not just the food they are consuming or the products they are buying for their skin, hair, etc. but even the packaging that it comes in. Thus making industries adopt sustainability faster than ever.

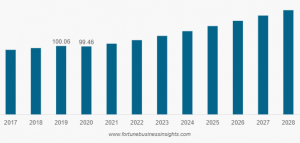

The Green packaging market alone is projected to reach $385 billion by 2028 with a CAGR of 5.3%.

The technological advancement to make packaging more reliable and secure further led industry players to utilize emerging technologies in packaging.

Besides top companies, startups are also making progress in packaging to a great extent. Their new innovative materials are strong enough to compete with plastic without sacrificing the environment, thus becoming the top trend in the packaging industry.

In this article, we will talk about 5 packaging industry innovation trends for sustainable solutions.

Further, to get the whole report, including the top 10 packaging industry innovation trends plus the companies and startups dominating it, please fill out the form below:

Here are the top 5 packaging innovation trends:

Trend 1: Plant-Based Packaging

Plant-based plastics, also known as bioplastics, are biodegradable and recyclable polymers made from renewable biomass sources such as maize, straw, and other crops. These are environmentally friendly because they are derived from plants. Unlike most petroleum-based plastic packaging, plant-based polymers will disintegrate under the correct conditions. A rising number of environmentally friendly and health-aware consumers are going plant-based. (Source)(Source)

Tetra Pak supplied 13.5 billion plant-based packages and 7.5 billion plant-based caps in 2020. Both plant-based packages and caps were manufactured of segregated plant-based polymers that could be entirely traced back to sugarcane. (Source)

Due to its chemical and physicochemical features, such as non-toxicity, biodegradability, processing versatility, film-forming ability, low water vapor permeability, grease/oil proof, and bio-compatibility, Zein (a protein derived from corn) emerges as a strong candidate to replace synthetic plastics in the development of active and bio-active food packaging. (Source)

The global green packaging market was valued at around $267.83 billion in 2021. The green packaging market includes bioplastics, recyclable paper & plastics, plant-based biomaterial, organic fabrics, and refurbished products. The degradable packaging market is estimated to hold approximately 8% share of the green packaging market and has been valued at $21.43 billion in 2021. (Source)(Source)

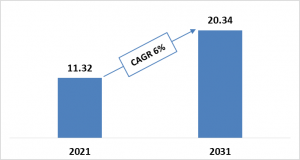

The degradable packaging market consists of plant-based and other bio-based materials. As the bio-based packaging market has been estimated to hold a market worth $10.11 billion in 2021, it can be extrapolated that the global plant-based packaging market was valued at around $11.32 billion in 2021.

The global sales of plant-based packaging are expected to grow at 6.7% in 2021. It is estimated that plant-based packaging will grow at a CAGR of 6% during 2022-2031 and reach $20.34 billion by 2031. (Source)

Global Plant-Based Packaging Market during 2021-2031 ($Billion)

Advantages of Using Plant-Based Packaging

Creates No Pollutants – The use of plant-based packaging has significant environmental advantages. It creates no pollutants when it decomposes, uses less carbon in production, and minimizes the quantity of garbage sent to landfills. Plant-based packaging may increase the client base as people’s environmental consciousness grows. (Source)

Easier and More Economical to Recycle – Plant-based plastic is simpler and less expensive to recycle than other substitutes for petroleum-based plastics. Coke’s switch to plant-based plastics for packaging was intended to boost the firm’s brand image and increase sustainability. (Source)

Reduces The Usage of Natural Resources – The technique of making plant-based packaging is quite simple, and the ingredients required to generate it are easily obtained from plants, as opposed to the high utilization rate of natural resources used to produce approximately 230 million tonnes of plastic bags each year.

Free From All The Allergens And Toxins – Consumers are safer from allergens and chemicals associated with non-biodegradable packaging. The majority of plastic-based packaging is non-toxic and allergy-free. (Source)

Companies and Startups working on Plant-Based Packaging

Xampla (Founding Year – 2018)

Xampla, based in the United Kingdom, is a specialist in the development of plant-based plastic alternatives that assist industrial enterprises in reducing their dependency on petroleum-based packaging. (Source) Innovative Technology- Supramolecular engineered protein (SEP) technology is used by the startup to create bio-based products from plant protein. The company enables industrial, agricultural, FMCG, and cosmetics industries to employ bio-based plastic alternatives for product packaging. (Source)

Sana Packaging (Founding Year – 2016)

The cannabis industry’s pioneering ecological packaging brand, Sana Packaging, designs and produces cannabis packaging for a circular economy. It uses 100% plant-based hemp plastic, 100% recycled ocean plastic, and other reusable materials. Sana Packaging products are all child-resistant, recyclable, food-grade, and manufactured in the United States to support regional agriculture and industry. (Source)

Vegware (Founding Year – 2008)

One of the world’s leading experts in plant-based compostable food service packaging is Vegware, with headquarters in the United Kingdom. In order to be commercially biodegradable with food waste, Vegware is produced from a variety of renewable, plant-based, reduced-carbon, recycled, or recovered materials.

Vegware packaging is biodegradable in industrial settings in its completed state. The business has the broadest range of compostability certifications available in the market, which is an independent assurance that its products may be processed in the right settings. Vegware has operations in the UK, USA, Hong Kong, and Australia and is sold in 70 countries. It is distributed in Europe, the Middle East, South America, and the Caribbean. (Source)(Source)(Source)

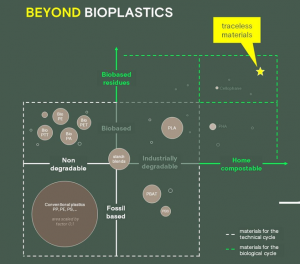

Trend 2: Bio-Based Packaging

Bio-based packaging material is produced from biodegradable and renewable raw materials coming from nature, either directly or indirectly. It is utilized as an environmentally friendly alternative to non-renewable, petroleum-based materials that are used for packaging. Bio-based materials are being used more and more in the sustainable packaging industry as the consumer market is moving toward greener packaging and less waste. It is anticipated that this trend would accelerate the expansion of the market for bio-based packaging during 2021-2028.

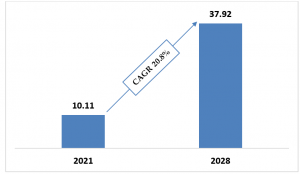

The global bio-based packaging market was valued at around $10.11 billion in 2021 and will reach around $37.92 billion by 2028, growing at a CAGR of 20.8%. (Source)(Source)(Source)(Source)

Global Bio-Based Packaging Market during 2021-2028 ($Billion)

Advantages of Using Bio-Based Packaging

High Flexibility – Alterations and modifications can be made to bio-based materials to get certain packaging goals. Changes can be made to the textures, forms, substrate thicknesses, and coatings. Due to this high level of flexibility, bio-based materials can deliver packaging solutions that are both more versatile and more cost-effective. (Source)

Minimum Environmental Impact – Most bio-based materials are biodegradable, which implies that bacteria can break them down into their naturally obtained components. This not only lowers the damage that the box has on the environment but also helps to make the package more environmentally friendly and sustainable. (Source)

Highly Appealing – The consumer market has a favorable attitude toward bio-based products due to their perceived environmental friendliness. Due to its widespread acceptance, a product can become more marketable, and the flexibility of bio-based materials assists to offer product packaging that is both environmentally friendly and aesthetically appealing. (Source)

Companies and Startups working on Bio-Based Packaging

TIPA (Founding Year – 2010)

Based in Israel, TIPA is attempting to resolve environmental issues associated with flexible plastic packaging without leaving any harmful residues or microplastics behind. TIPA has created unique biodegradable packaging solutions for the food sector. This packaging solution breaks down organically in up to 180 days in industrial compost. Its patent-protected formulations are a combination of totally compostable polymers that provide TIPA films and laminate qualities comparable to ordinary plastic. TIPA has optical, mechanical, and barrier qualities such as high transparency, printability, high sealing strength, high impact, and high barrier. (Source)(Source)(Source)

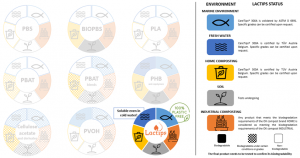

Lactips (Founding Year – 2014)

Lactips, based in France, excels in the manufacturing of plastic that dissolves and does not leave any trace in the surrounding environment. It develops water-soluble and biodegradable thermoplastic pellets based on casein, a milk protein which has well-known plastic characteristics. CareTips® is Lactips’ patented technology and the first casein-based substance that is 100% bio-sourced and biodegradable. Plastic Free Paper is a paper packaging coating developed and introduced by Lactips in 2021. It is free of plastic and PFAS and can be fully recycled and composted. (Source)(Source)(Source)(Source)

Trend 3: Food Waste and Agriculture Residue-Based Packaging

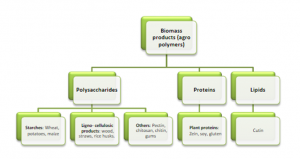

A large volume of agricultural processes generates a significant volume of agro-waste produced by companies dependent on agriculture. These wastes are often dumped in landfills or used in compost production, which are conventional disposal methods. Thus, these wastes can be used as raw material for the development of biodegradable and sustainable packaging material due to their diverse composition, including cellulose, hemicelluloses, proteins, and lipids. These packaging options are a great alternative to synthetic materials used for packaging. (Source)

Main Polymers of Agricultural Origin from Renewable Resources

Advantages of Using Food Waste and Agriculture Residue-Based Packaging

Increased Shelf-Life – Packaging films made from coconut water and lime peel extract hold antioxidant characteristics. Thus, have the potential to extend the shelf life of food products. They do so by improving their ability to act as a water barrier and reducing the amount of synthetic packaging material used. (Source)

Cost Reduction – By removing plastic, food manufacturers and retailers can avoid paying taxes on plastic. This will lead to a reduction in their overall carbon emissions. (Source)

Added Income – The waste generated from the farm can be turned into packaging material. Thus making the farmers earn money while removing something they no longer need. This gives farmers access to new sources of earnings by maximizing the value of agricultural byproducts and wastes. (Source)(Source)

Less Wastage – Utilizing agro-waste is a cost-effective way to create sustainable and eco-friendly packaging. These packaging alternatives reduce waste and the environmental impact of petrochemical-based synthetic packaging. (Source)

Companies and Startups working on Food Waste and Agriculture Residue Based Packaging

Traceless Materials (Founding Year – 2020)

Based in Germany, the start-up in the circular bio-economy provides a holistically sustainable alternative to plastics and bioplastics. They can turn agricultural industry residues into unique materials. These include traceless film, traceless plast, and traceless coat.

The patent-pending technology of Traceless creates a substance from agricultural waste that may be composted at home and in natural circumstances. The innovation emits up to 87% less CO2 than ordinary virgin plastic. The innovative material’s quality is comparable to that of traditional plastics and bioplastics. (Source)(Source)(Source)

Traceless Materials

Craste (Founding Year – 2018)

Craste, based in India, produces packaging products using an innovative technique. As a result, the water usage is reduced, and there’s Zero Level Discharge (ZLD) from the pulping unit. All their packaging is food-grade, made from agricultural waste, and straw panel board, and uses a formaldehyde-free glue. Patented Technology- It manufactures packaging materials and particle boards from stubble obtained from farmers. Fumasolv, a patent-pending technology that removes lignin to generate packaging solutions, is also being used by the firm to build packaging solutions from agricultural leftovers. (Source)(Source)

Trend 4: Renewable and Recyclable Packaging

Renewable packaging is designed to leave a less ecological impact when it is created, consumed, and after its expiration. Renewable packaging is the use of bio-based and natural resources in the manufacture of a package that can be refilled naturally. Recyclable packaging is made of materials that can be reused after being processed.

The material used in recyclable packaging is reintroduced into the manufacturing cycle. Several companies choose recyclable materials as they seek to lessen their environmental impact or landfill waste production. (Source)(Source)(Source)

A major trend among buyers concerned about sustainability is Renewable and Recyclable Packaging. The use of recyclable packaging is becoming increasingly popular in the packaging and produce industry. Several firms are currently exploring recyclable methods for their product packaging, as consumers increasingly prefer eco-friendly stamped products. (Source)(Source)

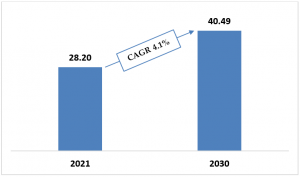

The Renewable and Recyclable Packaging Market was valued at $28.20 billion in 2021 and will reach around $40.49 billion in 2030, growing at a CAGR of around 4.1% during the forecast period. (Source)

Global Renewable and Recyclable Packaging Market during 2021-2030 ($Billion)

Advantages of Using Renewable and Recyclable Packaging

Targeting the Green Market – There is a rising market of consumers who are willing to spend more money to ensure that their products are environmentally friendly. Recyclable packaging assists in repositioning and targeting those customers who are willing to purchase eco-friendly products. Consumers currently expect at least 50% recycled content in plastic packaging, and few are ready to pay a premium for recycled plastic packaging. (Source)(Source)

Improving the Brand: Business can improve their brand and products in the target market by completing their corporate social responsibility. Consumers are more likely to buy from businesses that are prepared to invest in environmental conservation.

Cost Reductions: Recyclable packaging requires an initial investment, but it is feasible to save costs by reduction of the number of materials that need to be eliminated. Plastic recycled packaging allows for more energy-efficient production processes. (Source)(Source)

Companies and Startups working on Renewable and Recyclable Packaging

Ecoplasteam (Founding Year – 2017)

Ecoplasteam is an Italian firm that creates environmentally friendly raw materials from the garbage. The company produces a regenerated particle made of polyethylene and aluminum called EcoAllene. It is manufactured by recycling tetra packs, which are constructed of layers of cellulose, plastic, and aluminum, using patented technology.

EcoAllene is a colorable, sparkly substance that is eternally recyclable. Due to its great moldability, the material is utilized to produce packaging bottles. EcoAllene is also used in the fashion, building, and consumer goods industries. (Source)

SwapBox (Founding Year – 2019)

Based in the Netherlands, SwapBox is a zero-waste packaging firm that only develops and manufactures reusable packaging for the food and beverage industries. SwapBox’s packaging innovation strives to be environmentally friendly by recycling materials. The packaging may be reused up to 500 times, saving 500 disposable packagings.

By reusing materials in two ways, SwapBox’s packaging concept seeks to be environmentally friendly. The first step is to create packaging that can be used at least 300 times and maybe 500 times before being recycled. The second is recycling in a closed loop, which means that all SwapBox packaging goods that are no longer usable will be returned to the producers. The microwavable bowls of SwapBox are designed and manufactured in Belgium and are composed of 100% recyclable polypropylene. (Source)(Source)(Source)

Trend 5: Edible Packaging

Edible packaging is a form of sustainable packaging produced from plant-based materials. Thus, it is natural and biodegradable. Films and coatings are the two types of edible packaging. The distinction is that films are created separately and then placed into the food product, whereas coatings are produced and placed directly into the food. They can be simple coatings or layers between food product compartments.

Milk proteins are utilized as casein around food products in a novel kind of edible packaging. These casein coatings keep food fresher and less exposed to oxygen than plastic. By developing delicious gelatin packaging for an entirely natural sweet delight, businesses such as Loliware have been contributing to the movement toward a plastic-free future. (Source)(Source)(Source)

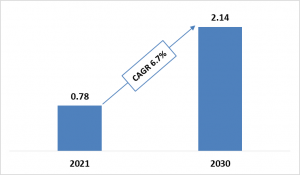

The global edible packaging market was valued at around $783.32 million ($0.78 billion) in 2021. The market will increase and reach around $2.14 billion by 2030, growing at a CAGR of 6.7%. (Source)

Global Edible Packaging Market during 2021-2030 ($Billion)

Advantages of Using Edible Packaging

Reduces Amount of Plastic Waste Produced – Many edible packaging solutions have a lower shelf life than other packaging options since they are water-soluble, which means they degrade in water. These films also frequently contain edible and renewable materials, giving them the significant advantages of being biodegradable and environmentally friendly. (Source)(Source)

Applied to a Variety of Uses – The most typical uses of edible packaging are for single-serve and chilled goods. This range might be widened to encompass soup and coffee, enabling the packaging to dissolve when heated. Milk casein can be used to coat cereal to prevent it from going to waste in place of sugar coatings to preserve certain foods, such as cereal. (Source)

Prolongs the Life of the Product – In general, edible films for packaging are effective at preventing moisture exchange between food products and the environment. This way, microbial development, textural changes, and unwanted chemical and enzymatic reactions are prevented. It maintains quality and increases the product’s shelf life which is reactive to oxygen. (Source)

Companies and Startups working on Edible Packaging

Skipping Rocks Lab (Notpla) (Founding Year – 2014)

Skipping Rocks Lab, based in the United Kingdom, focuses on natural, biodegradable liquid packaging materials created from seaweed and other plant resources. The startup is motivated by how nature wraps liquids utilizing membranes, from egg yolk to cells or fruits, as well as traditional food technologies such as Spherification techniques for packaging. Skipping Rocks Lab’s first breakthrough product is Ooho, a natural, flexible container for liquids that biodegrades in 4-6 weeks or may even be eaten.

It is composed of Notpla, a sustainable packaging material developed by the company that combines seaweed and plants. The water-filled spherical package is made of brown seaweed extract and calcium chloride and can contain water, soft drinks, sauces, or even alcohol. (Source)(Source)(Source)(Source)

Do Eat (Founding Year – 2013)

A Belgian startup that produces edible or highly biodegradable containers and packaging made from potato and beer waste as an alternative to disposable plastic. Do Eat packaging is gluten-free, has no additives, fats, or sugars, and is perfect for vegetarians and those following a kosher or halal diet. As the products of Do Eat have a neutral flavor, they may be utilized in both sweet and savory applications such as muffins, cupcakes, and other baked goods, and they are great for aperitifs or product samples.

Conclusion

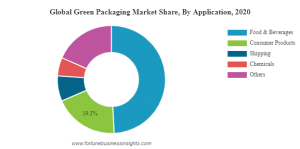

Packaging is crucial for many industries that’s why companies of multiple industries are also researching packaging innovation. But whatever the industry, sustainable packaging is the priority. The Food & Beverage industry has almost 50% of the sustainable packaging market.

That’s why when you see companies that adopt or research sustainable packaging, Food & Beverage companies would surely be present there.

In our sustainable packaging report, we have showcased market trends, research innovation, new materials, and top companies and startups working on them.

Click here to read about other Sustainable Packaging solutions.

Authored By: Vipin Singh, Market Research.